4shorts

Elite Member

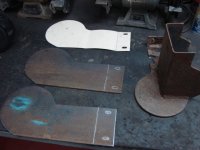

Had a few guys asking me how I cut the hols in my plate with the plasma. Well yesterday I had to cut a 3" hole in some 1/2 " plate. the smaller the hole the harder it is for my circle cutter because it don't have that short adjustment on it but I frigged with it enough to get it to work.

A few years back I made a lazy Suzy for my cabinet blaster to lay the heavy parts on it while blasting. To cut the cycle I take that Lazy Suzy and turn it upside down as seen in the photo's. I lay an old brake rotor on it and lay the plate on the rotor. I center punch the plate and ground the plasma clamp to the Lazy Suzy. I place the plasma torch/circle cutter on the plate and pull the trigger. As soon as it burns through I use my other hand and turn the flat bar while the plasma torch is not moving. As you can see it cuts a pretty descent hole. The rest of the plate was sheared on the Ironworker.

I know you all like pictures so here's a few to look at

A few years back I made a lazy Suzy for my cabinet blaster to lay the heavy parts on it while blasting. To cut the cycle I take that Lazy Suzy and turn it upside down as seen in the photo's. I lay an old brake rotor on it and lay the plate on the rotor. I center punch the plate and ground the plasma clamp to the Lazy Suzy. I place the plasma torch/circle cutter on the plate and pull the trigger. As soon as it burns through I use my other hand and turn the flat bar while the plasma torch is not moving. As you can see it cuts a pretty descent hole. The rest of the plate was sheared on the Ironworker.

I know you all like pictures so here's a few to look at