ACHINBAC

Silver Member

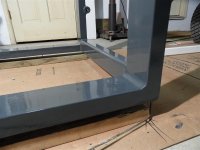

Got the prime coat on last night and will start work on a box & dolly for it next week.

The forks and the verticals are nested C channel, the pin receivers are DOM tubing, the cross bars are 1/4" wall box, and the elbow was filled and welded with scrap to stiffen it up. Most parts out of the scrap pile in the shed.

The forks and the verticals are nested C channel, the pin receivers are DOM tubing, the cross bars are 1/4" wall box, and the elbow was filled and welded with scrap to stiffen it up. Most parts out of the scrap pile in the shed.

Attachments

-

DSC04402 (Medium).JPG138 KB · Views: 202

DSC04402 (Medium).JPG138 KB · Views: 202 -

SAM_0854 (Medium).JPG73.5 KB · Views: 267

SAM_0854 (Medium).JPG73.5 KB · Views: 267 -

SAM_0861 (Medium).JPG68.3 KB · Views: 196

SAM_0861 (Medium).JPG68.3 KB · Views: 196 -

SAM_0847 (Medium).JPG62.7 KB · Views: 245

SAM_0847 (Medium).JPG62.7 KB · Views: 245 -

SAM_0869 (Medium).JPG63.8 KB · Views: 262

SAM_0869 (Medium).JPG63.8 KB · Views: 262 -

SAM_0866 (Medium).JPG54.8 KB · Views: 187

SAM_0866 (Medium).JPG54.8 KB · Views: 187 -

SAM_0865 (Medium).JPG62.3 KB · Views: 188

SAM_0865 (Medium).JPG62.3 KB · Views: 188 -

SAM_0863 (Medium).JPG56.6 KB · Views: 175

SAM_0863 (Medium).JPG56.6 KB · Views: 175