Following is my attempt using this concept. My biggest problem is not having enough time to work on it. This was last years project; havn't had time to play with it this heating season.

HOW TO BURN WASTE MOTOR OIL IN A GAS FURNACE

F U R N A C E S H E L L

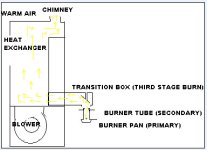

I used a salvaged gas furnace for the shell and the heat exchanger but removed the electronic controls, gas valve and burners and left the blower fan remaining. A couple of changes must be made to the heat exchanger system in order for the burner system to work. First the draft hood must be made air tight in order to maintain chimney draft suction all the way down to the burner. Next I fabricated a steel box to connect three of five heat exchanger tubes to the oil burner assembly which will stand in front of the furnace shell. After testing the burner, I determined that it will burn about one half gallon of waste oil per hour at the high burn setting which at 150,000 BTU per gallon calculates to about 75,000 BTU input. The gas furnace was a 125,000 BTU input and used a five tube heat exchanger so I figured that three tubes should be used for my heat exchanger.

B U R N E R

The burner design concept was borrowed from the You Tube poster name 徹zzirt at this link address:

YouTube - Drip Feed Waste Oil Heater

I used a burner tube from an old fuel oil furnace for the secondary burn tube and drilled 26 - 7/16 holes for draft air inlet.

The top of the tube has cast iron fins to swirl the flame. I think a ten inch length of four inch black pipe would work just as well if you do not have access to a burner tube like this.

This burner is mounted to a steel plate and beneath is a removable 6 inch cast iron fry pan for the primary burner fire pot. A ス X 6 inch pipe nipple is the oil inlet from the fuel pump.

Below is a picture of a test burn that I set up with a two pound coffee can as fuel storage and the air bubbler pump submerged. I fitted a 6 inch furnace pipe above the burner assembly that went directly into a masonry chimney for the test. This type of burner is not at all finicky to start and burn and takes only about 5 to 10 minutes to get it up to running temperature. I use about four or five squirts of kerosene from my pump type oil can and then point a propane torch flame for about 3 seconds down the primary air hole and it starts right up. A low to medium oil volume is best for the first five minutes of burn time until the unit gets hot enough to accept the high volume setting. Primary combustion air comes in at three locations. Two 7/16 inch holes are in the steel plate over the fire pan and the third inlet is the half inch pipe for the oil inlet. This pipe terminates at the center of the burner and has the top of the pipe cut away to form an open trough. This is just enough air to combust the oil into a very rich flame mixture which then rises into the secondary combustion burner tube where the air rushes in to burn the mixture with a bright white flame and a muffled roaring sound. Above the burner, the third combustion stage happens in the steel transition box that carries the hot gasses to the heat exchanger. The six inch round cut-out that came from the bottom of the transition box is mounted on a forty five degree angle just above the opening and serves two purposes. First it helps divert the hot combustion gasses from its vertical path to a horizontal path on its way to the heat exchanger, and second, since it is mounted above the hot combustion gasses by an open one half inch pipe mounting that allows additional air into the flame path while it glows a bright red color from the heat, it allows any unburned fuel one more chance to burn. The open pipe also provides a peek hole directly down into the burner to monitor it. My non-contact laser thermometer showed963 degrees F on the burner tube on one of the tests.

I am very pleased with the low amount of smoke that this burner generates. It is not completely smokeless, but you really have to look for it. I read stories of how users had to chisel residue deposits out of pot type burners but after about seven to eight hours of tests I just turned the pan up side down and tapped it once and only fine ash dropped out.

F U E L P U M P

Fuel (Waste motor oil) is fed into the furnace burner by an air bubbler pump which is a very simple pump made out of a one/ eighth inch brass flare tee. Oil comes in the bottom of the tee, air comes in the side and oil and air go out the top. The air is supplied by a tiny vibrating aquarium air pump. The volume of oil that is pumped per minute is affected by the static level of the oil in the pump tube and also by the temperature of the oil.

T A N K

I use a salvaged 10 gallon tank from a kerosene torpedo heater for fuel storage and it is adjustable in height with a crank system which regulates the static oil height in the pump tube and consequently the amount of oil pumped to the burner. The drain plug is replaced with a brass flare elbow fitting and connected to the bubbler pump with a clear flexible vinyl tube. This allows the tank to move up and down apart from the stationary bubbler pump. The tank is intentionally off level away from the oil exit fitting to allow water and other impurities to accumulate at the low end for later cleaning with the use of a small lever action suction device thru the fill opening. A 15 watt incandescent bulb with magnetic attachment heats the tank near the oil outlet for better oil flow in cold weather.

F U E L G A U G E A N D P U M P V O L U M E I N D I C A T O R

The tank had an opening top center for the fuel line of the torpedo heater which is now used for a fuel gauge, but more importantly it shows the range of bubbler pump oil volume to the burner. A vertical wire supported by a float protrudes thru the center hole and rises and lowers in keeping with the oil level and slides thru an indicator supported independently that shows high and low burn rates. Every inch of oil in the tank is about 1.74 gallons which is equal to about three and a half hours of burn time at one half gallon per hour burn rate. The working range of oil in the bubbler pump is about an inch and a half from high burn to low burn, so no adjustment is needed for about four hours unless you want to fine tune the heat output. This really works good because start-up is at high heat when it is needed most to warm up the shop, then it automatically gradually reduces the heat output over the next 4 hours when I don稚 need as much heat anyway. If I need more heat than the low setting after or near the end of the first 4 hours, I just crank up the tank to a higher level within the range of the indicator wire for another four hours or so of heat.