You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-Point Hitch Problems

- Thread starter CompactTractorFan

- Start date

- Views: 11893

More options

Who Replied?

/ 3-Point Hitch Problems

#21

CompactTractorFan

Super Member

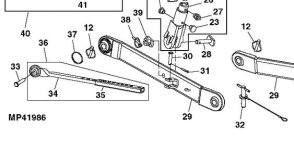

That seems like an inconvenient form of sway control. You may want to fab something like this with a pin adjustment.:thumbsup:

View attachment 194001

Now that I got the hang of it, I don't think I'll need anything else...

JDGreenGrass

Veteran Member

Glad you got that figured out. Looking at those turnbuckles...I don't think I would like them, either.?? Do they "dangle" when you have them loose.??...I think Not.??

Like I said before, my carry-all is a bugger to hook up. Part of the reason is that once you install your planking of wood it leaves no space for the 3pt. arms to go back beyond the pins. I know, it's hard to explain.....

In your last series of photos look at the first frame. Look at how your 3pt. arm (the very end) is flush to the frame of your carry-all. Now, imagine your carry-all with the wood in place. The arm is going to collide with the wood, leaving no wiggle room to hook up.

The thought just came to me to leave a void in the wood where the pins are.

Does anyone understand.??:laughing:

My carry-all is the lightest attachment I have and it is the worst gosh darn hook up that gets to swearing everytime. I'd rather hook up my snowblower, as I mentioned earlier in this thread.

Kyle, it is important to understand the turnbuckles. When you get a heavier attachment on there you'll want to be certain that the attachment will not "sway" into your tires. A bit of sway is good in most cases, but keep it to a minimum....say no more than 2 or 3 inches of sway. (or less).

Soo much to learn. I'm right there with ya.

Like I said before, my carry-all is a bugger to hook up. Part of the reason is that once you install your planking of wood it leaves no space for the 3pt. arms to go back beyond the pins. I know, it's hard to explain.....

In your last series of photos look at the first frame. Look at how your 3pt. arm (the very end) is flush to the frame of your carry-all. Now, imagine your carry-all with the wood in place. The arm is going to collide with the wood, leaving no wiggle room to hook up.

The thought just came to me to leave a void in the wood where the pins are.

Does anyone understand.??:laughing:

My carry-all is the lightest attachment I have and it is the worst gosh darn hook up that gets to swearing everytime. I'd rather hook up my snowblower, as I mentioned earlier in this thread.

Kyle, it is important to understand the turnbuckles. When you get a heavier attachment on there you'll want to be certain that the attachment will not "sway" into your tires. A bit of sway is good in most cases, but keep it to a minimum....say no more than 2 or 3 inches of sway. (or less).

Soo much to learn. I'm right there with ya.

CompactTractorFan

Super Member

Glad you got that figured out. Looking at those turnbuckles...I don't think I would like them, either.?? Do they "dangle" when you have them loose.??...I think Not.??

Like I said before, my carry-all is a bugger to hook up. Part of the reason is that once you install your planking of wood it leaves no space for the 3pt. arms to go back beyond the pins. I know, it's hard to explain.....

In your last series of photos look at the first frame. Look at how your 3pt. arm (the very end) is flush to the frame of your carry-all. Now, imagine your carry-all with the wood in place. The arm is going to collide with the wood, leaving no wiggle room to hook up.

The thought just came to me to leave a void in the wood where the pins are.

Does anyone understand.??:laughing:

My carry-all is the lightest attachment I have and it is the worst gosh darn hook up that gets to swearing everytime. I'd rather hook up my snowblower, as I mentioned earlier in this thread.

Kyle, it is important to understand the turnbuckles. When you get a heavier attachment on there you'll want to be certain that the attachment will not "sway" into your tires. A bit of sway is good in most cases, but keep it to a minimum....say no more than 2 or 3 inches of sway. (or less).

Soo much to learn. I'm right there with ya.

The turnbuckles do not dangle, they are rigid. When I was taking the pictures I was thinking the same thing about there not being any room to hook up the lift arms...About it swaying, I watched a video earlier and the guy explained all about the swaying...

tommu56

Elite Member

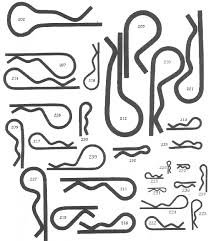

I'm talking about replacing the cotter pins with these: R-clip - Wikipedia, the free encyclopedia

most people call them hairpin clips or hitch pins

Google Image Result for http://www.smithfast.com/images/hitchpic1.gif

CompactTractorFan

Super Member

most people call them hairpin clips or hitch pins

Google Image Result for http://www.smithfast.com/images/hitchpic1.gif

Yeah, that's what they are called...:thumbsup:

CompactTractorFan

Super Member

JDGreenGrass, I was just thinking...What do you think of just putting a piece of plywood on the back of the carryall (just the width of the frame)...Do you think that will help with hooking it up???

Runner

Elite Member

- Joined

- May 12, 2007

- Messages

- 3,844

- Location

- Missouri

- Tractor

- 2024 Cub Cadet Ultima ZTXS5 54, 2007 John Deere 2520, 1989 John Deere 185, 1960 Panzer T70B

All of the above is the exact reason I went with a quick hitch. Even if I have to adapt some of the "non i-Match compatible" implements, once that is done, I never have to screw around with this stuff any more.

Something to think about.

Something to think about.

Leejohn

Elite Member

mjncad

Super Member

I'd say it's time the OP considered a Quick-Hitch, and use cotter-rings instead of the various pins mentioned. Check out McMaster-Carr www.mcmaster.com and search for cotter rings.

gwdixon

Elite Member

Thanks for the help everyone!!! :thumbsup: I was able to get the nuts loose and get everything tight and level. Now I have one last question: to get the implement off, I just turn the main nut the opposite way and leave the stop nut in the same spot, right? Oh, and here are the pics:

You have the right idea for removal of the carryall.

It is a PIA to keep turning that turnbuckle each time you put on an implement, however.

Larger tractors have the turnbuckle (or chains) on the outside of the arms so it is simply a matter of swinging the arm wide and then swinging them back to mount to the pins - no adjustments necessary. That is why teg mentioned earlier to turn the lift pins on the carryall to the inside. Then your lift arms would swing out to engage the lift pins.

However, a trick I used was to remove one of the pins from the clevis on the end of the turnbuckle. That frees up the arm to swing out and then back to connect. Then put the pin back in and no adjustments have to be made. A "hairpin" clip on the clevis makes it much easier.

Finally, I ended up getting a Pat's Easy Hitch and all of this nonsense was over. Just back up, lift the arms to engage the pins, hook up the top link and away you go.

JDGreenGrass

Veteran Member

JDGreenGrass, I was just thinking...What do you think of just putting a piece of plywood on the back of the carryall (just the width of the frame)...Do you think that will help with hooking it up???

Yes, that would work in most cases. Just remember that there may come a time that you wished you had a wider "wall." For instance, you may fit more firewood on the carry-all if you use a full length of wood.

But, as others are suggesting, a quick hitch may be the best option. I don't have a quick hitch and frankly I don't feel the need for one. I don't change attachments all that often.

And, to back up a bit, I think pressure treated decking would be ideal for material to finish off the carry-all. 1x6 or 1x8.

rd_macgregor

Veteran Member

- Joined

- May 14, 2008

- Messages

- 1,875

- Location

- Prince Edward Island, Canada

- Tractor

- Kioti DK45SC, Kubota B2650

Like I said before, my carry-all is a bugger to hook up. Part of the reason is that once you install your planking of wood it leaves no space for the 3pt. arms to go back beyond the pins. I know, it's hard to explain.....

My carryall box is made from 2X lumber and that hookup problem was obvious from the get-go. A small spacer between the upright arms and the box lumber would have solved the problem, but, since I didn't want to have to redrill all the holes, I just chiseled/sanded out a bit of cavity in the offending boards to give the ends of the lift arms some clearance for hookup.

As for replacing cotter pins with linch pins or hairpins...I use both types for convenience, but you need to check them often. More than once, I have lost a pin (both kinds) in brush. This included losing the pin that held one of the lift arms onto the tractor while mowing brush... with bad results (the lift arms are now bolted on!).

BOB

radioman

Super Member

This is what I did. I hate the turnbuckles. I'm making the adjustable side links now.

Interesting. you cut the whole thing in half and added sliding bars. how is that working out for you?

Leejohn

Elite Member

radioman,

It works real good!!!!! They were kind of hard to make, or I should say harder then the others I made. You can't see it in the picture, but the ends have to swivel just a little. I'm working on a better way to do that right now. Also the plate was kind of hard to cut, I don't have a band saw.

It works real good!!!!! They were kind of hard to make, or I should say harder then the others I made. You can't see it in the picture, but the ends have to swivel just a little. I'm working on a better way to do that right now. Also the plate was kind of hard to cut, I don't have a band saw.

CompactTractorFan

Super Member

All of the above is the exact reason I went with a quick hitch. Even if I have to adapt some of the "non i-Match compatible" implements, once that is done, I never have to screw around with this stuff any more.

Something to think about.

Since all we have now is the carryall, I think we will wait on the quick hitch.

CompactTractorFan

Super Member

This is what I did. I hate the turnbuckles. I'm making the adjustable side links now.

Nice Setup!!! :thumbsup:

CompactTractorFan

Super Member

You have the right idea for removal of the carryall.

It is a PIA to keep turning that turnbuckle each time you put on an implement, however.

Larger tractors have the turnbuckle (or chains) on the outside of the arms so it is simply a matter of swinging the arm wide and then swinging them back to mount to the pins - no adjustments necessary. That is why teg mentioned earlier to turn the lift pins on the carryall to the inside. Then your lift arms would swing out to engage the lift pins.

However, a trick I used was to remove one of the pins from the clevis on the end of the turnbuckle. That frees up the arm to swing out and then back to connect. Then put the pin back in and no adjustments have to be made. A "hairpin" clip on the clevis makes it much easier.

Finally, I ended up getting a Pat's Easy Hitch and all of this nonsense was over. Just back up, lift the arms to engage the pins, hook up the top link and away you go.

It is actually not to hard to turn the turnbuckles.

CompactTractorFan

Super Member

My carryall box is made from 2X lumber and that hookup problem was obvious from the get-go. A small spacer between the upright arms and the box lumber would have solved the problem, but, since I didn't want to have to redrill all the holes, I just chiseled/sanded out a bit of cavity in the offending boards to give the ends of the lift arms some clearance for hookup.

As for replacing cotter pins with linch pins or hairpins...I use both types for convenience, but you need to check them often. More than once, I have lost a pin (both kinds) in brush. This included losing the pin that held one of the lift arms onto the tractor while mowing brush... with bad results (the lift arms are now bolted on!).

BOB

I was able to get the carryall hooked up. It was a pain, but was not too bad...