The angled blades not only move the material back up to the crown but the material moving across the blade fills any ruts and depressions a straight blade may miss. I built a drag type one years ago, from about 3" angle iron that had the front blade angled one way, part way across the 6' wide square frame, a second blade behind it to move the material back the other way and a third straight blade in back to level any windrows out.

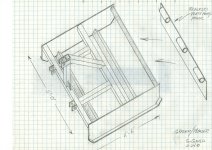

I also posted here before about a boxblade modified for spreading blacktop as below.

If anyone already owns a boxblade, you can achieve the basicly same bridging affect by adding 4-6 ft angle irons with the fronts turned up, to the sides of your boxblade. I anchored mine at the front of the box and slotted the box at the rear so the runners could be adjusted up and down, to adjust the height of the cutting edge to lay a specific depth if you're working with loose material.