dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,016

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

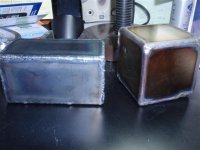

Just for giggles the instructor had us doing a few random things in our final class Thurs. I wanted to try TIG, so he set me and another student up. We used some 12-14 ga steel and SS. I didn't bother with Alum as I don't have AC capability on my home unit. It really wasn't too bad. If you can get the puddle to bridge the joint to get going it will just flow right in there. Pretty cool. Here's the better stuff...

Other than a couple quick trial runs on a coupon these were pretty much the first TIG runs I ever did (and also my last, so far). The cube is SS on the right. I used some 0.045 filler when the gap required it, but otherwise it was just fusion welds, especially on the SS.

My TA MST400 welder is capable of Lift TIG, so I may get that set up one of these days when I need it (and have space). I could see that being handy. Mostly just need a torch and tank (plus supplies/consumables). Foot Pedal is not required but could help. It was nice to taper off with the pedal at the ends so you didn't burn through.

Other than a couple quick trial runs on a coupon these were pretty much the first TIG runs I ever did (and also my last, so far). The cube is SS on the right. I used some 0.045 filler when the gap required it, but otherwise it was just fusion welds, especially on the SS.

My TA MST400 welder is capable of Lift TIG, so I may get that set up one of these days when I need it (and have space). I could see that being handy. Mostly just need a torch and tank (plus supplies/consumables). Foot Pedal is not required but could help. It was nice to taper off with the pedal at the ends so you didn't burn through.