Gary Fowler

Super Star Member

- Joined

- Jun 23, 2008

- Messages

- 11,998

- Location

- Bismarck Arkansas

- Tractor

- 2009 Kubota RTV 900, 2009 Kubota B26 TLB & 2010 model LS P7010

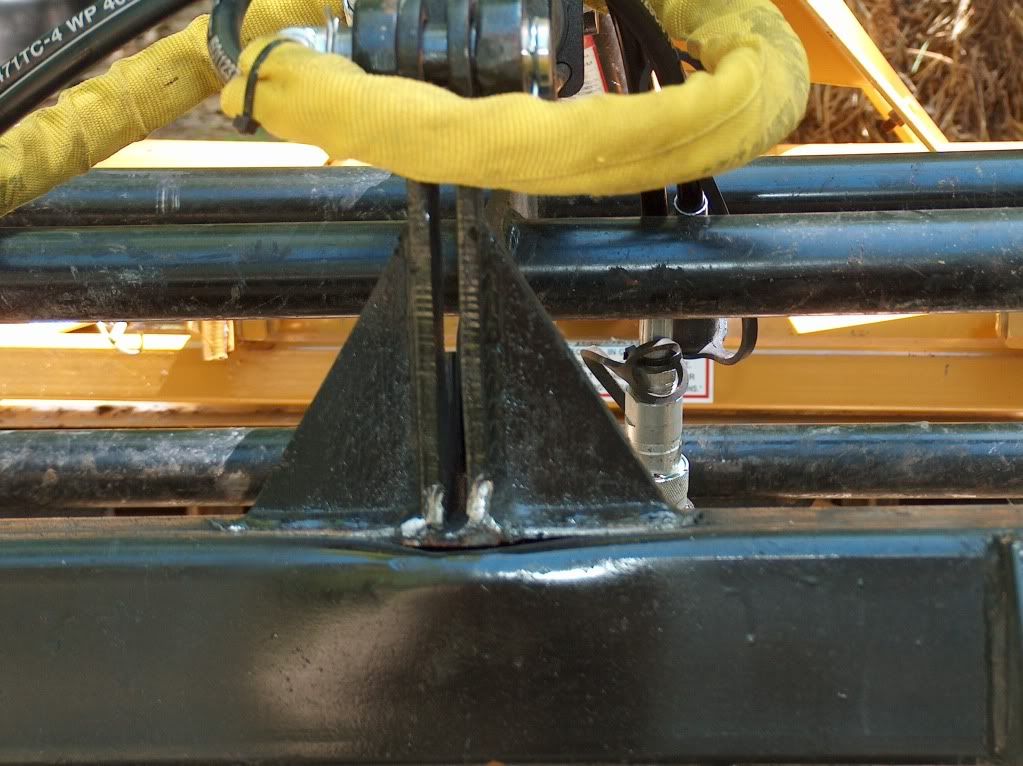

I guess folks are going to have to buy themselve a D-meter (digital thickness meter) to check the wall thickness on stuff like there where they enclose the ends. Tapping with a metal probe will give you a pretty good indication of thickness also. OF course buying via internet is not likely to turn up anything till it is on your tractor and broke.