LogChain

Member

Well, it finally happened. A gust of wind on the leading edge of a thunder storm took down one of my black walnut trees--one that had been ailing for several years. The tree had stood ~70 feet tall, was ~18" in diameter at its base, and was located ~100 yards from the house in a wooded area difficult to reach except by foot. Because of its size and location, it was not a good candidate for the local portable saw mill operator, but was of great interest to me as a hobbyist woodworker. Sadly, I am way overdue in making my youngest daughter her dresser  . So with a nudge from Mother Nature, let the fun begin :licking:!

. So with a nudge from Mother Nature, let the fun begin :licking:!

I've been following MotorSeven's "The Log house Project begins ........" thread http://www.tractorbynet.com/forums/projects/156451-log-house-project-begins-32.html for several years and have especially enjoyed seeing what he has done with his portable saw mill (e.g, ~ Post 315). I thought I might share with interested TBN members a smaller scale project using a smaller scale saw mill--the Granberg 36" Alaskan Saw Mill. I hope to show the steps to harvest successfully black walnut lumber from a single isolated tree.

The Alaskan Saw Mill is a rectangular frame that clamps to the bar of a chain saw. I use a Husqvarna 3120 XP power head with a 32" bar and a rip chain. The saw has plenty of power (8.4 hp) and a trigger lock--two features which are important for portable saw mill use.

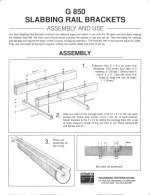

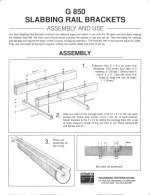

I also use the Alaskan Saw Mill G 850 slabbing rail brackets for the first cut of a log. Instead of using 2 x 4's for rails as suggested in the instructions, I use a pair of 10' perforated steel UniStrut channels. They seem to be straighter and stiffer than 2 x 4's and don't tend to get cut up for other purposes and be unavailable when needed for slabbing.

Before slab cutting (or live sawing) the logs, I limbed the tree and cut the top and branches in 22" lengths for firewood. Other trees that were in the fall line of the walnut were also cut into fire wood. My "orange tractor" (the 5.5 hp DR Power Wagon--it's all I've got ) was convenient to bring the fire wood up the hill to the house for splitting. I may be one of only a few TBN members whose chain saw can out power his/her tractor.

) was convenient to bring the fire wood up the hill to the house for splitting. I may be one of only a few TBN members whose chain saw can out power his/her tractor.

Next, two logs 9' 6" long were cut from the trunk, and the lower log was pulled into a convenient position for slabbing with my log winch/skidder (human powered at about 0.25 hp :sweatdrop . Although this setup lacks a LogChain (my moniker), it's light and effective.

. Although this setup lacks a LogChain (my moniker), it's light and effective.

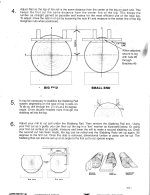

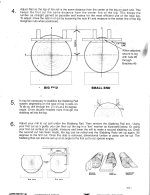

Then the two rail brackets were leveled and attached at opposite ends of the log equidistant from the log center (in this case ~6.5") with four duplex-head 20p nails. The two 10' UniStrut rails were finally placed on the brackets roughly parallel to each other and secured with nuts.

After setting the rails, the day was getting late, and I was getting tired so I decided to delay slabbing until this coming weekend. Yes, I've got a job. Please stay tuned .

.

-- LogChain

I've been following MotorSeven's "The Log house Project begins ........" thread http://www.tractorbynet.com/forums/projects/156451-log-house-project-begins-32.html for several years and have especially enjoyed seeing what he has done with his portable saw mill (e.g, ~ Post 315). I thought I might share with interested TBN members a smaller scale project using a smaller scale saw mill--the Granberg 36" Alaskan Saw Mill. I hope to show the steps to harvest successfully black walnut lumber from a single isolated tree.

The Alaskan Saw Mill is a rectangular frame that clamps to the bar of a chain saw. I use a Husqvarna 3120 XP power head with a 32" bar and a rip chain. The saw has plenty of power (8.4 hp) and a trigger lock--two features which are important for portable saw mill use.

I also use the Alaskan Saw Mill G 850 slabbing rail brackets for the first cut of a log. Instead of using 2 x 4's for rails as suggested in the instructions, I use a pair of 10' perforated steel UniStrut channels. They seem to be straighter and stiffer than 2 x 4's and don't tend to get cut up for other purposes and be unavailable when needed for slabbing.

Before slab cutting (or live sawing) the logs, I limbed the tree and cut the top and branches in 22" lengths for firewood. Other trees that were in the fall line of the walnut were also cut into fire wood. My "orange tractor" (the 5.5 hp DR Power Wagon--it's all I've got

Next, two logs 9' 6" long were cut from the trunk, and the lower log was pulled into a convenient position for slabbing with my log winch/skidder (human powered at about 0.25 hp :sweatdrop

Then the two rail brackets were leveled and attached at opposite ends of the log equidistant from the log center (in this case ~6.5") with four duplex-head 20p nails. The two 10' UniStrut rails were finally placed on the brackets roughly parallel to each other and secured with nuts.

After setting the rails, the day was getting late, and I was getting tired so I decided to delay slabbing until this coming weekend. Yes, I've got a job. Please stay tuned

-- LogChain

Last edited: