Kzooandy

New member

BX 25D Need a little help on Hydraulics for a 3 Point Log Splitter

As one other poster has done, I picked up an older Bush-Hog brand Log Splitter 3 Point mounted.

I want to just try running it with the BX25D on board pump and hydraulic ports, but confusion crept in and I'm hoping to get some input and help.

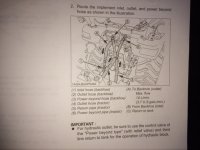

I have doctored some pictures and taken a shot from my manual.

First question What is Power Beyond? Or what does that refer to.

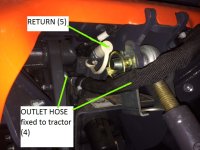

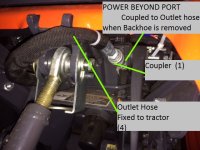

I have two lines on the splitter to couple to the tractor. An inlet and an outlet. HOWEVER... the tractor has an outlet hose, that loops to the Power Beyond Port on the tractor. And the Return pipe has a cap.

I would guess that the splitter return line, would go into the return pipe (white capped on tractor)

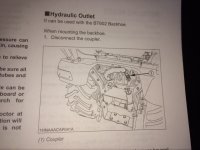

The mystery is trying to understand what the hydraulic fluid is doing when the backhoe is removed and that looped line is there.

If I hook up my inlet to the splitter to the (4) Outlet Hose Tractor (looped when backhoe removed) what do I do with the "power beyond" port that appears to be a return.

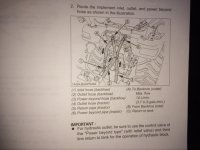

ALSO... If I combined the Power Beyond and the "tractor Outlet... would one get higher GPM. The tractor pump is rated at 6.2 GPM, but the Tractor Outlet hose (per the picture below) is only 3.7 GPM. I'm guessing the Power Beyond is also just an additional pump outlet? Would they be common or equal pressure from the pump? Would they combine to make close to the 6.2GPM. That's nearly double the output that could go to the splitter ram.

It's all a bit confusing so take a look at the pictures and tell me what you think.

Thanks for the help.

As one other poster has done, I picked up an older Bush-Hog brand Log Splitter 3 Point mounted.

I want to just try running it with the BX25D on board pump and hydraulic ports, but confusion crept in and I'm hoping to get some input and help.

I have doctored some pictures and taken a shot from my manual.

First question What is Power Beyond? Or what does that refer to.

I have two lines on the splitter to couple to the tractor. An inlet and an outlet. HOWEVER... the tractor has an outlet hose, that loops to the Power Beyond Port on the tractor. And the Return pipe has a cap.

I would guess that the splitter return line, would go into the return pipe (white capped on tractor)

The mystery is trying to understand what the hydraulic fluid is doing when the backhoe is removed and that looped line is there.

If I hook up my inlet to the splitter to the (4) Outlet Hose Tractor (looped when backhoe removed) what do I do with the "power beyond" port that appears to be a return.

ALSO... If I combined the Power Beyond and the "tractor Outlet... would one get higher GPM. The tractor pump is rated at 6.2 GPM, but the Tractor Outlet hose (per the picture below) is only 3.7 GPM. I'm guessing the Power Beyond is also just an additional pump outlet? Would they be common or equal pressure from the pump? Would they combine to make close to the 6.2GPM. That's nearly double the output that could go to the splitter ram.

It's all a bit confusing so take a look at the pictures and tell me what you think.

Thanks for the help.

Attachments

Last edited: