I am going to be butt welding a 6" wide by 1" thick piece of plate. It is not a critical part if it breaks but I don't want it to break.

Currently the part is made out of 6" x 1/2" plate and we have used it like that for 4 years and have had it break and had to re weld it maybe 5 times. My hope is with the thicker material it will last forever.

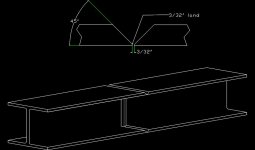

I have never really welded on material this thick before. I know I need to bevel it but can I just bevel it on one side or should I bevel it on both sides?

I was thinking of doing a 45 degree bevel using a piece on angle iron as a guide and my plasma cutter and doing it on just one side. The run a first pass with 6010 and then fill it up with 7018. The back side of the plate needs to be smooth so I was not even planning on welding the back at all but I can really build up the other side if need be.

Currently the part is made out of 6" x 1/2" plate and we have used it like that for 4 years and have had it break and had to re weld it maybe 5 times. My hope is with the thicker material it will last forever.

I have never really welded on material this thick before. I know I need to bevel it but can I just bevel it on one side or should I bevel it on both sides?

I was thinking of doing a 45 degree bevel using a piece on angle iron as a guide and my plasma cutter and doing it on just one side. The run a first pass with 6010 and then fill it up with 7018. The back side of the plate needs to be smooth so I was not even planning on welding the back at all but I can really build up the other side if need be.