I'm not ranting at you. I guess it just seems odd since I have 4 or 5 grease guns. I keep one in my backhoe. One in my mule for the tractors. And the rest are in my shop.

I've had my Workmaster 3 weeks and it has 38 hrs on it. I grease it every 10 hrs by the meter. Some say 8 hrs. But counting by 10 on the meter is easier to keep up with.

When you buy a gun get the flex tube if one doesn't come with it. When you buy grease buy the case. You will be surprised how fast it goes. And if your book doesn't show where all the fitting are, look it over real good. You will find fittings everywhere. Oil and grease are the blood of your machine. Greasing a machine is like brushing your teeth. You mite get away without doing for awhile but it's gonna catch up one day.

Oh and don't take the bottom off of the grease gun.

I get it... Basically my background is computer work - IT all the way. Heavy equipment is a new realm to be that become necessitated by the house and property we bought. Small property but needs a lot of work and the house... If we didn't have to live in it, it would have been much easier to tear it down and start over. Completely redoing the foundation, replacing all the main beams holding up the house, etc... All trying to work around our jobs, collecting, cutting, and piling firewood and trying to keep from running up against weather. Last fall we had 1/4 of our 1st floor completely removed and exposed to the elements when our first freeze came. It's all just been a constant race. Getting this tractor actually put me behind schedule for absolutely required work before being back into the cold this winter. No due to the tractor itself, but because I was going to rent equipment, but once I detailed out how long, how often, etc... I was putting an awful lot of money down the drain. So I decided to get the tractor with FEL and BH. But the whole process of changing direction, figuring out which tractor, finding a dealer of choice, financing, and waiting for delivery all set me back nearly a month during prime working time.

So, I'm stressed out. I didn't realize I missed the lubricating hours - I paid too much attention to the 3535 manual for maintenance and didn't really notice the maintenance stuff specific to the FEL and BH.

I'll get on it. Thanks for the info and queuing me to re-look at the maintenance stuff on these units better.

Things like that happen - being in the IT area - I can probably do the same with some of you guys though

When was the last time you opened the cover on your computers and cleared the dust out of the CPU and power supply fans? Cleared dust from the drive bays? Running the computer on and properly spec'd battery backup system, etc...

Ha! Just teasing! Although that stuff really should be done probably once a year or so - more or less depending on operating conditions - and IMHO - battery backups and proper surge suppression on all electrical pathways should be protected - not just power. Anyway, you see me point, this is an area new to me and it's not so obvious to a newbie like myself that I'd get it all right from the beginning without some poking and prodding.

My BH manual says lubricate every 8 hours and the FEL says lubricate every 5 hours. I would never have imagined these things would need lubed that frequently. Make me wonder how our poor vehicles survive.

Anyway, thanks, no hard feelings and sorry for the slight head biting!

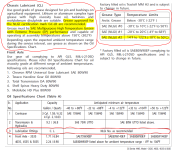

On the way to TSC today to get this stuff - although - I'm still not sure about which grease to get as my manuals are clear as mud on the topic. EP, EP2, NLGI #? - Sysop says EP2 stated in his manual, but I can't find where it says that in my manuals. Unless SAE (NLGI) #2 is EP2 - but I'm inclined to think not, as the #2 seems to be an indicator of ambient temperature ranges more so than assembly temperatures and stresses. I will take my spec sheet to TSC and see what they think too.