franklin2

Gold Member

You can run PVC with water lines, if it breaks you will get sprayed but that's about it. Using it with compressed air(or any gas) is different, when it breaks it's like a big spring behind it and throws shrapnel all over the place. You could use it if there is some sort of shield around it, but why go to all that trouble.

I have worked in factories for years and we always use black pipe. You will always get some water in the piping, and yes that will create rust. But there are ways to minimize it.

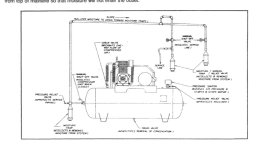

1. Your trunk line piping should be slanted toward the compressor. Ours fell toward the storage tank, but I am assuming your setup will have the tank and the compressor built together. Any water in the lines should run back to the tank where it can be emptied out on a regular basis. Low spots in the piping are where you get water puddling in the pipe, and that causes problems.

2. When you tap off the trunk line, you should point the tee up. I know it will be more work and more fittings, but that keeps the water in the trunk line migrating back to the tank instead of your drop. Come off the top, and using fittings to work it around the trunk line and down to the work area.

3. Like was mentioned, at the bottom of the drop don't use a elbow, use a tee with a valve pointing down where you can drain the drop if you need to.

Do all the above and use a filter with a sediment bowl, and you should not have any problems.

I have worked in factories for years and we always use black pipe. You will always get some water in the piping, and yes that will create rust. But there are ways to minimize it.

1. Your trunk line piping should be slanted toward the compressor. Ours fell toward the storage tank, but I am assuming your setup will have the tank and the compressor built together. Any water in the lines should run back to the tank where it can be emptied out on a regular basis. Low spots in the piping are where you get water puddling in the pipe, and that causes problems.

2. When you tap off the trunk line, you should point the tee up. I know it will be more work and more fittings, but that keeps the water in the trunk line migrating back to the tank instead of your drop. Come off the top, and using fittings to work it around the trunk line and down to the work area.

3. Like was mentioned, at the bottom of the drop don't use a elbow, use a tee with a valve pointing down where you can drain the drop if you need to.

Do all the above and use a filter with a sediment bowl, and you should not have any problems.