ericher69

Veteran Member

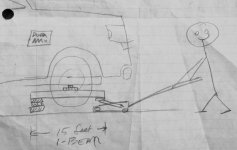

Purchased two lengths of used Ibeam that I will be splicing together.

This beam is for a trolley and small chain fall to help lift my b2920 implements to an acceptable working height. Max 500lbs.

Total span will be 15' when spliced.

Pieces are 11' and 4'

Beam is 5" by 3" by 1/2" thick

Here are some pictures

Prep, fit up and welding will be done by myself and directly supervised by a weldor with 30 years experience as a structural and high pressure weldor.

Will most likely weld with Millermatic 252.

Challenge will be clamping together so that it stays straight and doesn't warp.

Sent from my iPhone 5s 64Gb using TractorByNet

This beam is for a trolley and small chain fall to help lift my b2920 implements to an acceptable working height. Max 500lbs.

Total span will be 15' when spliced.

Pieces are 11' and 4'

Beam is 5" by 3" by 1/2" thick

Here are some pictures

Prep, fit up and welding will be done by myself and directly supervised by a weldor with 30 years experience as a structural and high pressure weldor.

Will most likely weld with Millermatic 252.

Challenge will be clamping together so that it stays straight and doesn't warp.

Sent from my iPhone 5s 64Gb using TractorByNet