Jorville

Bronze Member

- Joined

- Apr 14, 2012

- Messages

- 90

- Location

- Burnsville, MN.

- Tractor

- WD Allis, Case 580 CK, HD5 Allis crawler, Bantam Koehring track hoe,

I needed a hydraulic tank of a specific size so I built one for my hydraulic unit. The tank completely filled will hold 17 gallons, I keep it at 15 gallons. The tank holds a little over a gallon per inch. The first picture shows another tank where the pieces were cut out of. That truck that tank was on was scrapped out a year earlier. It would have been nice to have had the pieces sheared from new sheet metal. The pieces would have been perfectly square then. They are pretty close now. The sheet metal is ten gauge.

View attachment 442196

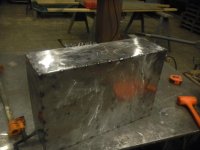

Tank with two sides and bottom with baffle welded together. The baffle is so the return oil can not just return on one end of the tank and go pretty much directly to the supply port.

tank tacked together without last side

Tank completely tacked together so corner welds can be made without filler rod. Tank was oxygen/acetylene gas welded together. The arc weld tacks were burnt into the weld as the corners were fused together without filler rod. Had to add a little filler rod once in a while when the bottom of corner had a little gap. After tank was completely welded together I had to vacuum out the tank. Tank had weld splatter inside it. The inlet and outlet ports were welded with 3/32 7018.

Tank on the wood splitter. I completely rebuilt the Hydraulic unit. Another engine, the old engine was crank start, sure is nice to have a starter motor. New hydraulic pump, all new hoses. The only thing from the old machine was the frame and cylinder and Valve and the parts on the beam.

View attachment 442196

Tank with two sides and bottom with baffle welded together. The baffle is so the return oil can not just return on one end of the tank and go pretty much directly to the supply port.

tank tacked together without last side

Tank completely tacked together so corner welds can be made without filler rod. Tank was oxygen/acetylene gas welded together. The arc weld tacks were burnt into the weld as the corners were fused together without filler rod. Had to add a little filler rod once in a while when the bottom of corner had a little gap. After tank was completely welded together I had to vacuum out the tank. Tank had weld splatter inside it. The inlet and outlet ports were welded with 3/32 7018.

Tank on the wood splitter. I completely rebuilt the Hydraulic unit. Another engine, the old engine was crank start, sure is nice to have a starter motor. New hydraulic pump, all new hoses. The only thing from the old machine was the frame and cylinder and Valve and the parts on the beam.

Last edited: