HumphreyUK

New member

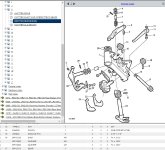

I am working on an old JD 219 baler. The knots would not tie, so I started looking for problems. The first think I noticed was the slackness on the stripper arm shaft. I took out the split pin on top and the two washers and pulled the shaft out. The first thing I noticed is that there is a hardened sleeve that fits closely on the 5/6" shaft. The fit of the sleeve on the knotter casting was very loose indeed with 0.008" wear.

I have a parts book that does not show a sleeve at all.

I am thinking of drilling a grease hole in the sleeve and Loctite-ing it to the housing. This will allow the shaft to run in the sleeve.

Has anyone done this? Are oversize sleeves available in case this does not work?

Humphrey

I have a parts book that does not show a sleeve at all.

I am thinking of drilling a grease hole in the sleeve and Loctite-ing it to the housing. This will allow the shaft to run in the sleeve.

Has anyone done this? Are oversize sleeves available in case this does not work?

Humphrey