norbie454

Member

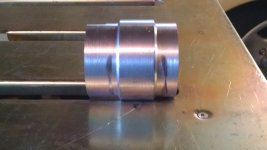

I tried to build a 2" square tube bender using my wood splitter but I seem to be doing more crushing rather than bending. Not sure but I am thinking I need a larger radius push die with a more robust center section and maybe some side plates. if anyone has done this before and been through the growing pains with any suggestions I would greatly appreciate it. Here are a few photos to show what I am up against.

I tried to build a 2" square tube bender using my wood splitter but I seem to be doing more crushing rather than bending. Not sure but I am thinking I need a larger radius push die with a more robust center section and maybe some side plates. if anyone has done this before and been through the growing pains with any suggestions I would greatly appreciate it. Here are a few photos to show what I am up against.

Last edited: