muddstopper

Veteran Member

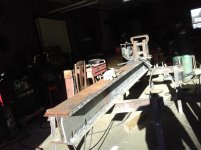

Got started back to my processor build after almost a year and half of surgeries and rehab. I had bought a box of hobart 1/8 7018 several months ago, but hadnot opened the box. Knowing I was going to be doing a lot of welding yesterday, I opened the box and laid them on top of my wood stove the nite before, just to make sure no moisture. I couldnt get those rods to run right at all. Rods would stick, flux would flake off, slag had to be beat off. I adjusted the welder up and down and even tried dc negative. I fought thur it until I had burnt the whole 5lb box. I had a few old rods that had been laying on top of the wood stove since last winter so i grabbed them and finished up. Those rods ran like they should, no sticking, no flux flaking off and you can certainly see the difference in the bead where I ran out with the new rods and started back with the old rods. Well, I had also bought another box of the hobart rods yesterday morning. I have been running those rods today, they seem to be doing better than the other new box of rods I bought months ago. Any ideal what could have been the problem with the first box of rods. Just a bad batch maybe??I will have to buy more new rods before the project is finished, but I think I will go to the welding supply and by what ever they sell, even tho the box I bought yesterday seem to be running ok. I usually dont buy over 5 lbs at a time because I dont use them all and it can be months before I fire up the welder again.