TomIre

Gold Member

Hope I can ask this clearly. This is a new FEL on a new 2017 3725 on case that makes a difference.

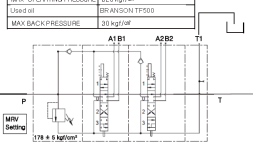

Should I be able to both lift the bucket and curl at the same time? Or, lower and dump? I feel like I can only do one operation at a time - lift the curl.

Is that the way the valves are setup? Or, is it possibly still new and stiff?

Should I be able to both lift the bucket and curl at the same time? Or, lower and dump? I feel like I can only do one operation at a time - lift the curl.

Is that the way the valves are setup? Or, is it possibly still new and stiff?