You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Container Weld Shop build -

- Thread starter BukitCase

- Start date

- Views: 107301

More options

Who Replied?

/ Container Weld Shop build -

#371

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Not a lot happening lately, been too much "life" gettin' in the way

I need to get those two new "high cube" containers moved into place (so I can stop moving so much stuff at least TWICE) and haven't been able to reach my "container guy" yet -

I do have two 3'x8'x 1/4" wall rectangular tubes coming manana (Monday) - they will be placed under each end of the pair of containers (see my floor plan sketch earlier) - the rectangular tubing will give the same "flotation" support as an 8" "H" beam, but at HALF THE WEIGHT they'll cost half as much - good thing, previously (before Tariff crap) I wuz paying around $.72-$.75 a pound for most shapes; these came in at $.92 a pound, which puts 'em at $318 for each 20' long stick. - STILL better than futzin' around with concrete and forms...

- STILL better than futzin' around with concrete and forms...

If I can't get my "container guy" or one of his friends, my "plan B" is to take an old (given to me) tandem axle trailer, cut off all but the subframe the springs fasten to, add a couple crossbars ABOVE that, and chain it to each container near the middle (AFTER picking one end up with the loader) and jockey them (almost) into place that way, then jack each one up and block them, finally letting 'em off the blocks and onto the rectangular tubes - when that part finally happens, I'll be sure to catch up on the picture shortage ...Steve

...Steve

I need to get those two new "high cube" containers moved into place (so I can stop moving so much stuff at least TWICE) and haven't been able to reach my "container guy" yet -

I do have two 3'x8'x 1/4" wall rectangular tubes coming manana (Monday) - they will be placed under each end of the pair of containers (see my floor plan sketch earlier) - the rectangular tubing will give the same "flotation" support as an 8" "H" beam, but at HALF THE WEIGHT they'll cost half as much - good thing, previously (before Tariff crap) I wuz paying around $.72-$.75 a pound for most shapes; these came in at $.92 a pound, which puts 'em at $318 for each 20' long stick.

If I can't get my "container guy" or one of his friends, my "plan B" is to take an old (given to me) tandem axle trailer, cut off all but the subframe the springs fasten to, add a couple crossbars ABOVE that, and chain it to each container near the middle (AFTER picking one end up with the loader) and jockey them (almost) into place that way, then jack each one up and block them, finally letting 'em off the blocks and onto the rectangular tubes - when that part finally happens, I'll be sure to catch up on the picture shortage

"Not a lot happening lately, been too much "life" gettin' in the way" Most likely that happens more the older we get so might as well go down memory lane and watch an old chainsaw that you used to use back in the day get rebuilt in 35 min. I thought it was neat.

Seized 196�s Chainsaw Restoration - YouTube

Seized 196�s Chainsaw Restoration - YouTube

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Watched the vid, pretty cool (other than using "fitzalls" instead of REAL wrenches  ) - the older I get, the closer to being that fast I USED to be

) - the older I get, the closer to being that fast I USED to be

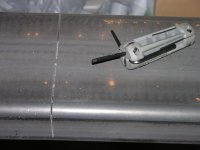

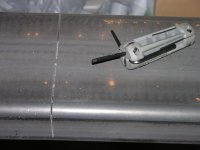

As Mark Twain reportedly said, "the rumors of my death have been greatly exagerated" - been fighting my Jet bandsaw off and on since it locked up during a cut on 3x8 tubing - Got this far on the 5th piece - originally thought it was a problem in the worm gear box, til I drained the lube -

originally thought it was a problem in the worm gear box, til I drained the lube -  -

-

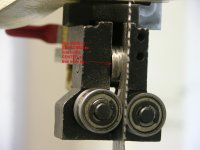

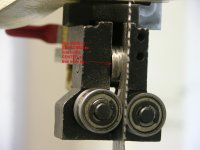

Next I discovered that all 5 bearings on the blade guide that's downstream of the cut were bad (felt noticeably rough when turned) -

- discovered I already had some "donors", surplus center find a couple years ago -

- discovered I already had some "donors", surplus center find a couple years ago -  - Got lucky when I drove the pin out on the BACK bearing; no mention of the knurling in the manual

- Got lucky when I drove the pin out on the BACK bearing; no mention of the knurling in the manual  -

-  - Ready to go back in (all 5 bearings in the pre-cut end were still fine) -

- Ready to go back in (all 5 bearings in the pre-cut end were still fine) -  - Made 3 more cuts on a brand new Starrett blade, saw locked up AGAIN - I'm omitting the copious quantities of swear words and tests/experiments, fast forward to conditions at present (enlarge pics for more details) -

- Made 3 more cuts on a brand new Starrett blade, saw locked up AGAIN - I'm omitting the copious quantities of swear words and tests/experiments, fast forward to conditions at present (enlarge pics for more details) -

At one point in all this, I was convinced that I'd over-tensioned the blade and it had been that way for about a year, and that the cast iron bow was WARPED - I haven't come up with a reason for the conditions in the last couple pics other than that.

At this point, I'm waiting for delivery of a Lenox blade, then I'll try that and the last NEW Starrett; tests on those will be at LOWEST tension they'll track, and if things are still "out of line" I'll have to decide between just buying a new BOW ($400, special order, 1 MONTH) or a whole new SAW ($1400 or more, shipped TOMORROW) - tough call, since at this time I'm nowhere NEAR 100% sure the bow will fix things.

That's the main reason I'm waiting on a "second opinion", AKA two different mfg.'s blades; if a different blade fixes this, it won't be the FIRST time I've been "led around the mulberry bush" by crappy blades (on OTHER saws) - I should know THAT part in a few days.

Enjoy the pics; I would too, if I knew what they meant Need to get this resolved and get the 2 hi-cube containers relocated before winter ...Steve

Need to get this resolved and get the 2 hi-cube containers relocated before winter ...Steve

As Mark Twain reportedly said, "the rumors of my death have been greatly exagerated" - been fighting my Jet bandsaw off and on since it locked up during a cut on 3x8 tubing - Got this far on the 5th piece -

originally thought it was a problem in the worm gear box, til I drained the lube -

originally thought it was a problem in the worm gear box, til I drained the lube -  -

- Next I discovered that all 5 bearings on the blade guide that's downstream of the cut were bad (felt noticeably rough when turned) -

- discovered I already had some "donors", surplus center find a couple years ago -

- discovered I already had some "donors", surplus center find a couple years ago -  - Got lucky when I drove the pin out on the BACK bearing; no mention of the knurling in the manual

- Got lucky when I drove the pin out on the BACK bearing; no mention of the knurling in the manual  - Ready to go back in (all 5 bearings in the pre-cut end were still fine) -

- Ready to go back in (all 5 bearings in the pre-cut end were still fine) -  - Made 3 more cuts on a brand new Starrett blade, saw locked up AGAIN - I'm omitting the copious quantities of swear words and tests/experiments, fast forward to conditions at present (enlarge pics for more details) -

- Made 3 more cuts on a brand new Starrett blade, saw locked up AGAIN - I'm omitting the copious quantities of swear words and tests/experiments, fast forward to conditions at present (enlarge pics for more details) -

At one point in all this, I was convinced that I'd over-tensioned the blade and it had been that way for about a year, and that the cast iron bow was WARPED - I haven't come up with a reason for the conditions in the last couple pics other than that.

At this point, I'm waiting for delivery of a Lenox blade, then I'll try that and the last NEW Starrett; tests on those will be at LOWEST tension they'll track, and if things are still "out of line" I'll have to decide between just buying a new BOW ($400, special order, 1 MONTH) or a whole new SAW ($1400 or more, shipped TOMORROW) - tough call, since at this time I'm nowhere NEAR 100% sure the bow will fix things.

That's the main reason I'm waiting on a "second opinion", AKA two different mfg.'s blades; if a different blade fixes this, it won't be the FIRST time I've been "led around the mulberry bush" by crappy blades (on OTHER saws) - I should know THAT part in a few days.

Enjoy the pics; I would too, if I knew what they meant

Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 7,047

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

Steve, I recently picked up a dual miter head Ellis saw (in need of lovin') for what I would have paid for in taxes and shipping on a brand new one. It ALSO had the "high clearance blade option"  like the photo you posted:

like the photo you posted:

I've had good luck with the import blades from Princess Auto on my other bandsaw but they didn't have the right length for the Ellis so I also ordered a Lennox online.

like the photo you posted:

like the photo you posted:

I've had good luck with the import blades from Princess Auto on my other bandsaw but they didn't have the right length for the Ellis so I also ordered a Lennox online.

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Terry, good score on the Ellis saw; hopefully it won't take more "love" than you can give to nurse it back to health - I would've LOVED having an Ellis, but wasn't willing to give TWICE as much as I paid for the Jet - I've gotten REALLY "gun-shy" about used gear around here, seems like the majority of tooling's been "rode hard and not put away AT ALL", then they'll put an ad on Craigslist AFTER they've priced something brand new, and think they're GIVING it away for 80% of RETAIL

Had some good/bad news of my own yesterday evening;

The bad: I was wrong about having another of the 6-10 tooth Starretts, I had THREE of the 10-14 tooth instead...

The good: I decided to try one of the finer pitch Starretts NOW rather than wait for the Lenox to show up - put it on the saw, followed Jet's kinda sketchy instructions for setting tension - blade now rides NEARLY centered on both back bearings. Finished half-dozen cuts on 2.5x2.5x.25 wall tubing with no hiccups - (Note to self: ALWAYS try a new blade FIRST...)

I have 4 more cuts to do on the 3x8x.25" wall tube, I have the saw aligned well enough to stand that tubing on EDGE for the cuts (maybe, hafta check clearance for an 8" TALL cut) - if I can get away with that, cuts should go faster by NOT having to cut 8" wide on the flat sides...

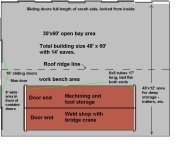

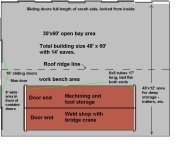

Forgot to mention - all these cuts (and some torch cuts on 3/4" plate) are for leveling/support "pads" for the two hi-cube containers that will be part of my new "last ditch effort" at a separate weld/machining/maintenance shop (spent a half hour tryin' to find the post with the floor plan, screw it; here's a re-post) -

No pics yet, each pad (6 total for the 8 container corners) will be a 16" x 27" base (3/4" plate) with "pyramids" centered on it, made of various sizes of square/rectangle tubing - these have been calculated to make the CONTAINERS level, even though the site is NOT (quite) -

If I'd already modded one of my tractors for hydraulic SIDE link I probably woulda worked harder to get the actual site scraped level, but it's too much of a PITA to accomplish that with a manual crank for side link. As it is, both ends of where the 2 containers go have a 5" drop side to side, plus the non-door end is 3" LOWER than the door end (hence the 3" tall rectangle tubes - then there's a 2-1/2" difference side to side at the mid-point (where 2 containers touch) and a 5" drop at the side where the REST of the building will be....

Those numbers are the reason for using 2-1/2" tubing (1 or 2 layers, depending) and 3" tubing (2 layers at the low end, ONE layer at the high ends) - pieces will all get welded together and CAPPED (I HATE "Squitters" - that's a made-up word for the combo of squatters and critters :laughing: )

Then the containers will be moved with a rollback CLOSE to their final resting place, and jockeyed/lifted to final position by me and a few hydraulic "friends", their "pyramids" set under and containers lowered into place. (kinda makes me tired just TYPING that )

)

Forgot to mention - those "pyramids" will replace (see floor plan) those 6x8 tubes (white bars in plan), supporting only the CORNERS of containers; center supports will be TWICE as wide to support corners where the two containers meet -

And yes, there WILL be pics; but first I gotta actually DO it... Steve

Had some good/bad news of my own yesterday evening;

The bad: I was wrong about having another of the 6-10 tooth Starretts, I had THREE of the 10-14 tooth instead...

The good: I decided to try one of the finer pitch Starretts NOW rather than wait for the Lenox to show up - put it on the saw, followed Jet's kinda sketchy instructions for setting tension - blade now rides NEARLY centered on both back bearings. Finished half-dozen cuts on 2.5x2.5x.25 wall tubing with no hiccups - (Note to self: ALWAYS try a new blade FIRST...)

I have 4 more cuts to do on the 3x8x.25" wall tube, I have the saw aligned well enough to stand that tubing on EDGE for the cuts (maybe, hafta check clearance for an 8" TALL cut) - if I can get away with that, cuts should go faster by NOT having to cut 8" wide on the flat sides...

Forgot to mention - all these cuts (and some torch cuts on 3/4" plate) are for leveling/support "pads" for the two hi-cube containers that will be part of my new "last ditch effort" at a separate weld/machining/maintenance shop (spent a half hour tryin' to find the post with the floor plan, screw it; here's a re-post) -

No pics yet, each pad (6 total for the 8 container corners) will be a 16" x 27" base (3/4" plate) with "pyramids" centered on it, made of various sizes of square/rectangle tubing - these have been calculated to make the CONTAINERS level, even though the site is NOT (quite) -

If I'd already modded one of my tractors for hydraulic SIDE link I probably woulda worked harder to get the actual site scraped level, but it's too much of a PITA to accomplish that with a manual crank for side link. As it is, both ends of where the 2 containers go have a 5" drop side to side, plus the non-door end is 3" LOWER than the door end (hence the 3" tall rectangle tubes - then there's a 2-1/2" difference side to side at the mid-point (where 2 containers touch) and a 5" drop at the side where the REST of the building will be....

Those numbers are the reason for using 2-1/2" tubing (1 or 2 layers, depending) and 3" tubing (2 layers at the low end, ONE layer at the high ends) - pieces will all get welded together and CAPPED (I HATE "Squitters" - that's a made-up word for the combo of squatters and critters :laughing: )

Then the containers will be moved with a rollback CLOSE to their final resting place, and jockeyed/lifted to final position by me and a few hydraulic "friends", their "pyramids" set under and containers lowered into place. (kinda makes me tired just TYPING that

Forgot to mention - those "pyramids" will replace (see floor plan) those 6x8 tubes (white bars in plan), supporting only the CORNERS of containers; center supports will be TWICE as wide to support corners where the two containers meet -

And yes, there WILL be pics; but first I gotta actually DO it... Steve

("At one point in all this, I was convinced that I'd over-tensioned the blade and it had been that way for about a year, and that the cast iron bow was WARPED - I haven't come up with a reason for the conditions in the last couple pics other than that. ")

Sounds like you having some of my luck come your way, your welcome. I dont think cast iron warps, it would think it'll break first. I thought the Jet brand was in the upper class of tools, this sounded like a HF problem, maybe the tool grades has reversed meaning HF is the best of the best, thanks for the update.

Gloom Despair And Agony On Me (marriage , money) - YouTube

Sounds like you having some of my luck come your way, your welcome. I dont think cast iron warps, it would think it'll break first. I thought the Jet brand was in the upper class of tools, this sounded like a HF problem, maybe the tool grades has reversed meaning HF is the best of the best, thanks for the update.

Gloom Despair And Agony On Me (marriage , money) - YouTube

OP

BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Nope, the TOOL is fine; it's the "tool" that's messin' with it  - at the moment, the saw is cutting dead on 90* in every direction with ZERO blade wander - I can hold a machinist's square up against all cuts, and they're exactly square no matter which side you put the square on. Can't ask for better'n that...

- at the moment, the saw is cutting dead on 90* in every direction with ZERO blade wander - I can hold a machinist's square up against all cuts, and they're exactly square no matter which side you put the square on. Can't ask for better'n that...

Near as I can tell now, I was 'WAY OVER on tension - I set it up with the new blade (after replacing the bad guide bearings) and just tightened it a bit over one turn past where the long side of the blade straightened out. Then I cut 5 more pieces of the 2-1/2 square 1/4" wall tube, watching the blade,guides, etc, for any sign of a problem (guards off, hands in pockets )

)

Manana I'll cut the last 3 pieces of 3x8 tubing, (I checked, and the max vertical on that saw is just a hair over 7" so those cuts will get done flat) then I'll put all the "sissy stuff" back on and move on to torch cuts on the 3/4 plate - clean up the slag on those, then lay out my "pyramids" and weld those, then cut some 1/4 FB and close off all the "critter condo's" - then I'll hose it all with primer, let dry, paint 'em, and nag my "container guy" to get off his tush and get the hi-cubes moved.

The "pyramids" will weigh around 190 pounds EACH, so I'll clamp one of the heavy weld clamps on 'em for a "picking eye", no sense makin' an eye for each one when it'll only get used ONCE - besides, they'd just be in the way...

Shouldn't be any problem tweaking the containers into final position; the hoe loader is noticeably stronger with the redone curl cylinder, and it could pick one end of a 40' container BEFORE - difference is, now it STAYS up :thumbsup: - between that and my modded 20 ton air jacks, couple of farm jacks, various bars, hammers, chains, etc, and they'll be where I want 'em when I'm done...

'Bout supper time, then there's new episodes of NCIS on the tube; later... Steve

Near as I can tell now, I was 'WAY OVER on tension - I set it up with the new blade (after replacing the bad guide bearings) and just tightened it a bit over one turn past where the long side of the blade straightened out. Then I cut 5 more pieces of the 2-1/2 square 1/4" wall tube, watching the blade,guides, etc, for any sign of a problem (guards off, hands in pockets

Manana I'll cut the last 3 pieces of 3x8 tubing, (I checked, and the max vertical on that saw is just a hair over 7" so those cuts will get done flat) then I'll put all the "sissy stuff" back on and move on to torch cuts on the 3/4 plate - clean up the slag on those, then lay out my "pyramids" and weld those, then cut some 1/4 FB and close off all the "critter condo's" - then I'll hose it all with primer, let dry, paint 'em, and nag my "container guy" to get off his tush and get the hi-cubes moved.

The "pyramids" will weigh around 190 pounds EACH, so I'll clamp one of the heavy weld clamps on 'em for a "picking eye", no sense makin' an eye for each one when it'll only get used ONCE - besides, they'd just be in the way...

Shouldn't be any problem tweaking the containers into final position; the hoe loader is noticeably stronger with the redone curl cylinder, and it could pick one end of a 40' container BEFORE - difference is, now it STAYS up :thumbsup: - between that and my modded 20 ton air jacks, couple of farm jacks, various bars, hammers, chains, etc, and they'll be where I want 'em when I'm done...

'Bout supper time, then there's new episodes of NCIS on the tube; later... Steve

Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 7,047

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

Oldpath: thanks for the vid. Which good lookin’ fella is you??

dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,548

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

Oldpath: thanks for the vid. Which good lookin’ fella is you??

I'm thinkin' second from the left.