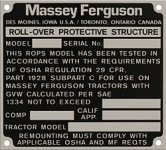

I have a machine like this. It has an enclosed cab but other than that the same. It has a flat bed that does not tilt. It weighs roughly 19,000 lbs.

I almost rolled it today and it scared the crap out of me. I doubt the cab could withstand a roll over.

I want to build a roll cage. I plan to redo the front grill guard (which is currently exactly like in the picture) and extend that up over the cab and tie it in to the flat bed. Basically I will have four vertical posts - two coming up from the grill guard and two coming up from the flat bed. All four tied together over the top of the cab.

The big question is what size material to use? Overkill is not a problem. Added weight is no issue. I was kind of thinking 4" x1/4" wall square tubing? Let me know you thoughts. I plan to gusset all joints and make it stout but I want to make sure the material is adequate.

As to what happened I was going down a steep hill, dropped over 100' in 200' and it started to slide. It turned sideways and slid about 50' to a stop and rocked sideways almost going over. Quite frankly it was one of the most scariest things I have ever had happen to me. All I could think about was the cab wasn't going to hold if it rolled and I was going to be crushed.