ArlyA

Super Star Member

- Joined

- Mar 18, 2016

- Messages

- 13,376

- Tractor

- Outlander1000 6x6, Ego lawn mower and shopping for tractor

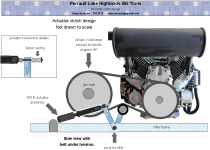

Folks, I'm not a ME and don't play one on YouTube.  I'm putting together a 35hp power drive and need it to be clutched. Since the engine could also use some load shock protection, I thought a few V belts attached right on the engine might work. Lets say 5" sheave on the output shaft but any size could be used, and 5" also on the secondary shaft. Of course an idler would be used and actuated, so as to give it a clutch. This would be operating at 3000rpm or nominal gas engine speeds and in cool temps, like below freezing. Bad or good idea?? And what size V-belt (more than one?) should be used? Thanks!

I'm putting together a 35hp power drive and need it to be clutched. Since the engine could also use some load shock protection, I thought a few V belts attached right on the engine might work. Lets say 5" sheave on the output shaft but any size could be used, and 5" also on the secondary shaft. Of course an idler would be used and actuated, so as to give it a clutch. This would be operating at 3000rpm or nominal gas engine speeds and in cool temps, like below freezing. Bad or good idea?? And what size V-belt (more than one?) should be used? Thanks!

Attachments

Last edited: