GKChesterton

Member

Bit of a newbie to working on a tractor, but I'm trying to do a lot on my own and learn as I go. Had an issue on a B7800 last weekend and was wondering if anyone has any advice. Tractor has been getting a little slow to start. I read some postings on here and figured it might be my switches were old/dirty and not carrying much charge so I bought a low voltage relay kit. When I started the tractor, it was slow to fire up as always. I ran it for an hour or two and parked it and went to move it into the barn to install the low voltage relay. When I went to fire it up. Nothing happened when I turned the key. I checked the treadle position, still nothing. I thought, wow, good timing on buying the relay, which I then installed. Tried the tractor. Instead of nothing, I got a bunch of clicks but starter would not turn over.

I next put a big jump starter on the battery positive to positive terminal and negative to the frame of the tractor. Just more clicks. I thought maybe I had a bad starter. After some tinkering, I connected the jump starter negative to the negative battery post (which I致e always been told not to do) and the tractor fired right up.

So, I think I have a bad battery and am planning to replace it. The tractor has a 51R, but I致e seen on here that folks have moved up to a Group 34 for more CCA. I知 planning to try the same unless someone would advise against. Here are my other questions though.

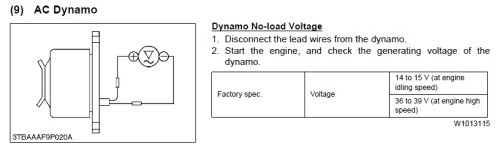

One, the battery I had on it was only a year and a half old. It started that morning, albeit sluggish, and it had been sitting for two weeks. After driving the tractor for two hours, battery should not have been dead a short time later. So, I could have a bad battery, but I知 also wondering if I might also need a new dynamo on the tractor (my understanding is the B7800 has a dynamo not an alternator). My understanding is I can test the dynamo with a volt meter while the tractor is running. Do you know what voltage I should be looking for with a dynamo? Around 14 volts?

Two, when I connected the jump starter to the frame, the tractor won稚 start, but when I connect to the negative post, it will start immediately. That didn稚 really make any sense to me and made me wonder if there is something other than a weak battery going on. When I was testing this, I tried a couple of different spots on the tractor and the loader to attach the negative cable and it never fired up.

Anyone have any thoughts on what might be going on? Am I just attaching the negative cable in all the wrong spots on the tractor?

I next put a big jump starter on the battery positive to positive terminal and negative to the frame of the tractor. Just more clicks. I thought maybe I had a bad starter. After some tinkering, I connected the jump starter negative to the negative battery post (which I致e always been told not to do) and the tractor fired right up.

So, I think I have a bad battery and am planning to replace it. The tractor has a 51R, but I致e seen on here that folks have moved up to a Group 34 for more CCA. I知 planning to try the same unless someone would advise against. Here are my other questions though.

One, the battery I had on it was only a year and a half old. It started that morning, albeit sluggish, and it had been sitting for two weeks. After driving the tractor for two hours, battery should not have been dead a short time later. So, I could have a bad battery, but I知 also wondering if I might also need a new dynamo on the tractor (my understanding is the B7800 has a dynamo not an alternator). My understanding is I can test the dynamo with a volt meter while the tractor is running. Do you know what voltage I should be looking for with a dynamo? Around 14 volts?

Two, when I connected the jump starter to the frame, the tractor won稚 start, but when I connect to the negative post, it will start immediately. That didn稚 really make any sense to me and made me wonder if there is something other than a weak battery going on. When I was testing this, I tried a couple of different spots on the tractor and the loader to attach the negative cable and it never fired up.

Anyone have any thoughts on what might be going on? Am I just attaching the negative cable in all the wrong spots on the tractor?