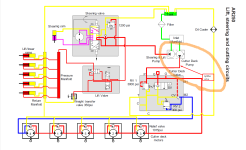

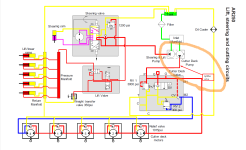

I have a ransome ar250 and its mowers are shot so are some of the hoses to the hydraulic motors and I have an older log splitter that the motor doesn't work and I want to create a mobile log splitter by combining the two. The pump is 30 Lpm so I don't think I need a 2 stage pump and its current relief valve says 3000 psi so I don't think it would have any issues ie. hoses and stuff blowing up due to too much pressure. The splitters control valve still works but I also have a Prince RD522CCAA5A4B1 that I would prefer to use, I cant find much info on the valve but I think it would work.

So far I have gotten the adapters(from 1/2" ORFS to 1/2" NPTF) so I can use my existing hoses on the splitter and just hook in before the switch for the mowers. Basically my questions are is this safe? I believe most wood splitter valves are basically pass through as long as its in the neutral position correct(mine didn't sound like it was stressing the motor until it hit the wood)? I am thinking about getting a pressure gauge to put in before the splitter valve for the final build, at the end I would like to completely remove the mower control valve and just have it return directly to tank so I don't have anything that could cause leaks/issues.

It has lift cylinders and controls that still work so I would like to eventually integrate a log lift but for now I want to just power the splitter. I kinda also want to make a hydraulic saw with the existing hydraulic motors but probably unrealistic.

So far I have gotten the adapters(from 1/2" ORFS to 1/2" NPTF) so I can use my existing hoses on the splitter and just hook in before the switch for the mowers. Basically my questions are is this safe? I believe most wood splitter valves are basically pass through as long as its in the neutral position correct(mine didn't sound like it was stressing the motor until it hit the wood)? I am thinking about getting a pressure gauge to put in before the splitter valve for the final build, at the end I would like to completely remove the mower control valve and just have it return directly to tank so I don't have anything that could cause leaks/issues.

It has lift cylinders and controls that still work so I would like to eventually integrate a log lift but for now I want to just power the splitter. I kinda also want to make a hydraulic saw with the existing hydraulic motors but probably unrealistic.