ArlyA

Super Star Member

- Joined

- Mar 18, 2016

- Messages

- 13,368

- Tractor

- Outlander1000 6x6, Ego lawn mower and shopping for tractor

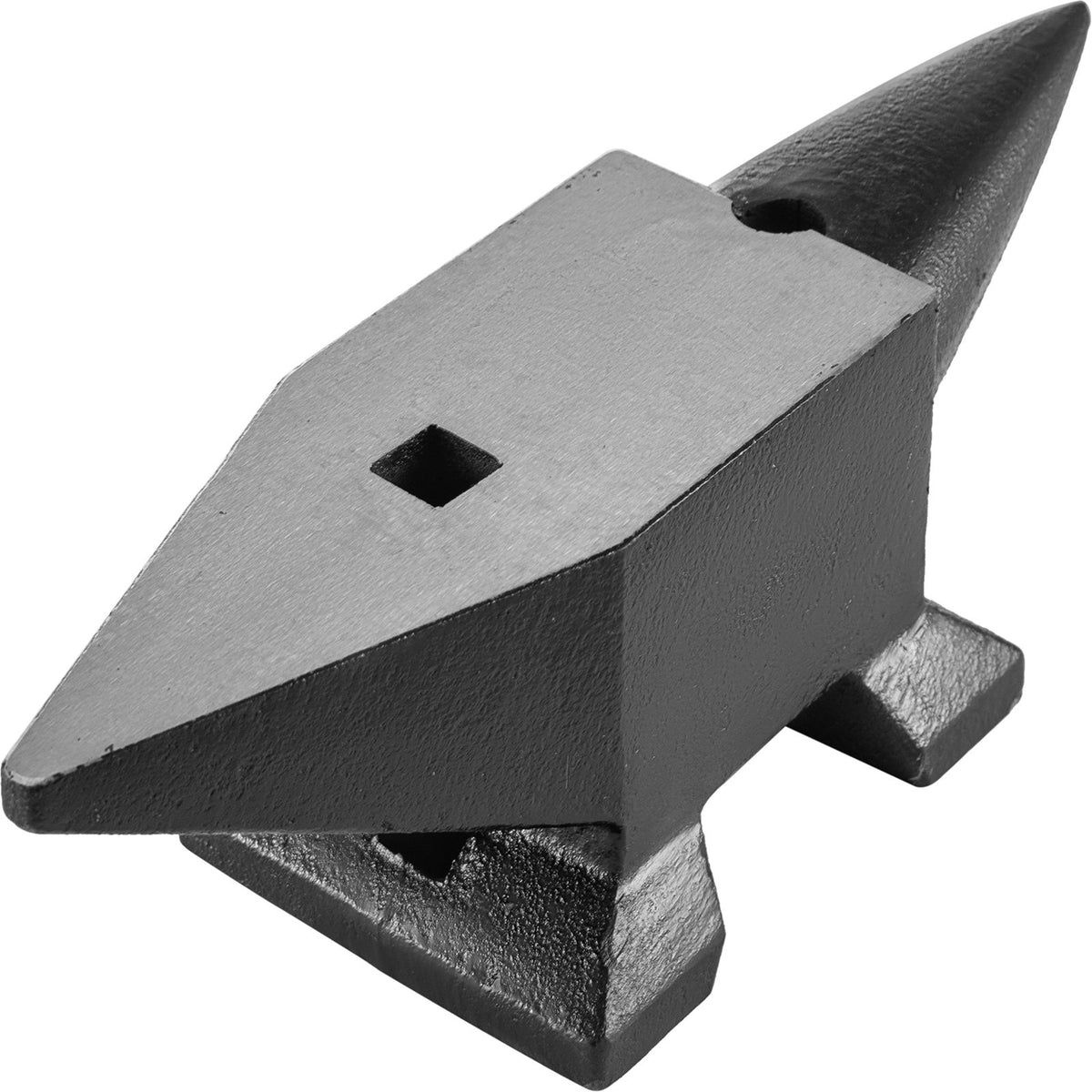

On Friday at work, I build this anvil stand. The anvil is quite heavy and I used a fork lift to get it on top. The rim is 40's truck vintage. The only cutting I did was via hand-help band saw to cut those angles and all parts seen were found in the lengths seen. I work at a metal recycling yard.  I should have put a hammer holding loop on it. I like to use rims so one person can roll it around by yourself. I've not used .045 wire before and getting to really like that size. What do you think of it?

I should have put a hammer holding loop on it. I like to use rims so one person can roll it around by yourself. I've not used .045 wire before and getting to really like that size. What do you think of it?