Zete

New member

- Joined

- May 2, 2022

- Messages

- 11

- Tractor

- 1996 Zetor 4320

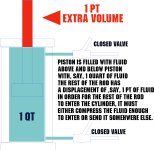

Thanks, the power steering is good. I will be looking for a new valve.If you do replace the control valve assembly that should take care of the loader drifting down so quickly. 2 spool control valves with PB and SAE threads are in the $250 to $400 range. Even a new control valve assembly will let a loader drift down over a few hours, but it will have tight enough internal clearances to slow the fluid from leaving the cylinders so quickly.

You said you want to check it yourself, and with the control valve assembly doing its job you can then add a pressure gauge on a hydraulic "T" fitting which will let you figure out if the cylinder internal seals are leaking or if the hydraulic pump has gotten weak....or both.

Hmmm....come to think of it, if your 3pt hydraulic circuit is independent of the FEL hydraulic circuit you could insert the pressure gauge on a "T" fitting back there to check the hydraulic pump right now.

Your shop manual should have a pressure vs RPM curve for that pump.

But it sounds so far like you are still going to need a new control valve to stop the FEL drifting down.

BTW, how is the power steering? Any clues there?

.