Oz_Kioti

Silver Member

I've had a WC88 for about six years now, working it probably 100 hours per year, on olive tree prunings mostly. Typical max size around 80mm or so diameter.

Recently it started making "noises" which turned out to be the flywheel hitting the inside housing of the chipper under the outlet shute when it was attached to the 3PL and working. On the ground, unhooked from the tractor, there was no contact, but very little clearance as well! And on the ground, the flywheel spun true and freely.

Turns out that the flange bearings rely on a tight friction fit to hold them precisely in place on the housing of the chipper. The four 14mm bolts through each flange have countersunk heads, thus cannot move in the chipper housing, however the holes in the flange bearings allow for some movement, so there's no way to positively lock the flanges in a fixed position on the housing. Just tighten them up as much as you dare, and hope the friction between the flange and the housing is adequate to prevent movement of the plane of the main shaft.

In my case, before loosening the bolts to thwack the flange bearing back to where it should be to centralise the shaft, we scribed a mark on all sides of the flange where it contacted the housing. After thwacking, the flange had moved about a millimetre back to where it should be. (1mm at the shaft = about 5mm on the edge of the flywheel) Coming from an aviation background, this sort of imprecise engineering would ring a few alarm bells. While it's only a wood-chipper, not a high performance aircraft, in principle I don't think Messrs Garrett, RR or P&W would approve!

So we're currently thinking of welding nuts on their ends to the housing, with bolts through to make hard contact with the flange, and jam nuts to keep the bolt hard up to the flange.

Apart from this issue, and one I've mentioned previously where the belts idler tension pully was too small in diameter for that class of belt (and verified by the belt manufacturer), I'm very happy with the machine.

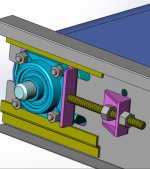

Here's how much the flange moved to get the flywheel running centrally again:

Recently it started making "noises" which turned out to be the flywheel hitting the inside housing of the chipper under the outlet shute when it was attached to the 3PL and working. On the ground, unhooked from the tractor, there was no contact, but very little clearance as well! And on the ground, the flywheel spun true and freely.

Turns out that the flange bearings rely on a tight friction fit to hold them precisely in place on the housing of the chipper. The four 14mm bolts through each flange have countersunk heads, thus cannot move in the chipper housing, however the holes in the flange bearings allow for some movement, so there's no way to positively lock the flanges in a fixed position on the housing. Just tighten them up as much as you dare, and hope the friction between the flange and the housing is adequate to prevent movement of the plane of the main shaft.

In my case, before loosening the bolts to thwack the flange bearing back to where it should be to centralise the shaft, we scribed a mark on all sides of the flange where it contacted the housing. After thwacking, the flange had moved about a millimetre back to where it should be. (1mm at the shaft = about 5mm on the edge of the flywheel) Coming from an aviation background, this sort of imprecise engineering would ring a few alarm bells. While it's only a wood-chipper, not a high performance aircraft, in principle I don't think Messrs Garrett, RR or P&W would approve!

So we're currently thinking of welding nuts on their ends to the housing, with bolts through to make hard contact with the flange, and jam nuts to keep the bolt hard up to the flange.

Apart from this issue, and one I've mentioned previously where the belts idler tension pully was too small in diameter for that class of belt (and verified by the belt manufacturer), I'm very happy with the machine.

Here's how much the flange moved to get the flywheel running centrally again: