ok bought ford 1900 4x4 with front loader knowing 3 point did not work , front loader works awesome, changed seal on piston the presses the rod that raises 3 point , seal was cracked bad , changed - no difference , loosened nuts on the end of controls (fast & slow control under front of seat ) no oil coming to control, whats next ??? any ideas, pull control unit from side ? THANKS !!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1900 3 POINT HITCH WON'T RAISE

- Thread starter toolhawk

- Start date

- Views: 25171

More options

Who Replied?

/ 1900 3 POINT HITCH WON'T RAISE

#1

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Yes, it sounds like the power beyond plug in your joystick valve has loosened and come out. It is normally an allen head threaded plug under another threaded cover that keeps the port sealed. When the plug is out, oil is returned to the reservoir rather than continuing through the open center system to the 3PH. The loader works fine, but the 3PH will not work because it never gets pressure. This has happened on several models of New Holland tractors. Do you have a New Holland loader? Is your joystick a New Holland joystick? If it is, I can look up the diagram and try to help you with the location of the Power Beyond plug.

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Is it the 771 loader? If it is a 771, I might have something for you to check. BTW: I'm not sure of the flow for your loader, but on most utility size NH tractors, there is a diverter valve that interrupts flow to the 3PH and routes it to the loader. The loader joystick valve then routes the fluid back to the diverter and onto the 3PH. New Holland does not make the joystick valves, but they do show detailed diagrams of the valves. If it's some other loader, then NH would not have any of their diagrams.

Another thing is the speed adjustment just affects the rate of 3PH drop. It does not change how fast the 3PH raises. Therefore, it only works when the 3PH is raised by metering how fast the fluid in the lift cylinder is allowed to escape back to the reservoir when the 3PH lever is moved down.

Another thing is the speed adjustment just affects the rate of 3PH drop. It does not change how fast the 3PH raises. Therefore, it only works when the 3PH is raised by metering how fast the fluid in the lift cylinder is allowed to escape back to the reservoir when the 3PH lever is moved down.

It is the 771 loader with victor control , where would I find a diagram ? I have the ff-44 book but does not show the loader stuff , just the pump. went to garage to look at the hyd. plumbing and this makes sense now. When you say diverter valve would this be in the loader controls ?? THANKS!!

JC-jetro

Elite Member

It is the 771 loader with victor control , where would I find a diagram ? I have the ff-44 book but does not show the loader stuff , just the pump. went to garage to look at the hyd. plumbing and this makes sense now. When you say diverter valve would this be in the loader controls ?? THANKS!!

toolhawk,

I just got your pm. can't add much more than Jim already said about power beyond port. I do not have a loader on my rig to have first hand knowledge. What I would do is to systematically follow the hyd pump discharge pipe and verify flow or lack there of. One way you can easily verify flow is right at the lift cylinder head. There is a port where you can attach a gauge. You can search under my handle for thread I started and you'll see where I'm talking about. If you remove that plug, put a bucket under you can verify flow. if no flow I would then manipulate lift handle all the way open and closed to see if it eject a blockage, same as passing kidney stone. You might also have a blockage in your lift spool valve where it revert all the flow back to diffy.If you have flow when you remove the plug and no movement of the arm then there is a possibility that over pressure relief on the cylinder head is reverting/by passing the flow to the diffy. Do you put any load on the 3 point when you try to raise it? Have you tried to raise it with no load on it. Can you with the tractor off and no load on the 3 point manually by hand lift the lift arm?... thinking may be ram rod is not pushing the piston or the pin that hold it to rock shaft is broken. Give us some more input and we might be able to steer you in the right direction.

JC,

went out this morning just to confirm , I can raise and lower arms freely , can look thru side with spool removed and rod is connected and moving when arms are raised and lowered, will reassemble and loosen banjo bolt carefully when running to see if any pressure is even getting to spool . THANKS!!!

JC-jetro

Elite Member

went out this morning just to confirm , I can raise and lower arms freely , can look thru side with spool removed and rod is connected and moving when arms are raised and lowered, will reassemble and loosen banjo bolt carefully when running to see if any pressure is even getting to spool . THANKS!!!

Okay, sounds good. One by one we need to eliminate potential cause of the problem. There were several other thing I suggested. Let us know what you'll find out.

JC,

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

It is the 771 loader with victor control , where would I find a diagram ? I have the ff-44 book but does not show the loader stuff , just the pump. went to garage to look at the hyd. plumbing and this makes sense now. When you say diverter valve would this be in the loader controls ?? THANKS!!

Toolhawk, I'm going to post a few illustrations below, but I have to tell you that I may be way beyond my expertise with your tractor. I'm beginning to think that your tractor may not have that "power beyond" plug on the loader control valve. I'm sure that the hydraulic flow is diverted to the loader ahead of the 3PH, but the bypass path I described may not be there. Looking at the piping diagram and the valve diagrams makes me think your loader controls are a whole different genre than the newer loader and valves. The last thing I want to do is mislead you and make you waste time chasing your tail. Without a hydraulic system schematic, I have to advise you to take my comments as well-intentioned, but not necessarily reliable.

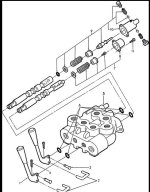

The diagrams below came from messicks.com. Go to this link. Enter your model number into the blank on the right side of the page (1900 or 771) and search through the parts diagrams. These show detailed breakdowns for both your 1900 tractor and 771 loader.

Attachments

Ok checked a few things with no luck,and called messicks , they told me to turn slot on block from 10 to 2 or other way , don't think the 1900 has that to divert front to rear ,

Hers what I did , loosened high pressure line that goes in under 3 pt controls , has pressure when running , pulled plug on side of lift cylinder head while running -no oil !!, backed off screw on control valve that bolt on spool and did effect the loader performance ,screwed back in , had no effect on 3 pt., I do have a pressure gauge but at am a loss what to check with nothing at lift cyl. head.. Thanks !!! for any help, and that messick site is awesome!!

Hers what I did , loosened high pressure line that goes in under 3 pt controls , has pressure when running , pulled plug on side of lift cylinder head while running -no oil !!, backed off screw on control valve that bolt on spool and did effect the loader performance ,screwed back in , had no effect on 3 pt., I do have a pressure gauge but at am a loss what to check with nothing at lift cyl. head.. Thanks !!! for any help, and that messick site is awesome!!

JC-jetro

Elite Member

Ok checked a few things with no luck,and called messicks , they told me to turn slot on block from 10 to 2 or other way , don't think the 1900 has that to divert front to rear ,

Hers what I did , loosened high pressure line that goes in under 3 pt controls , has pressure when running , pulled plug on side of lift cylinder head while running -no oil !!, backed off screw on control valve that bolt on spool and did effect the loader performance ,screwed back in , had no effect on 3 pt., I do have a pressure gauge but at am a loss what to check with nothing at lift cyl. head.. Thanks !!! for any help, and that messick site is awesome!!

The pic below is where I put the gauge. if you removed the plug and no oil cam out then we need to go backward to see where you have any flow.

The pic below is where the relif pressure device is. On mine when I had issue with the pump I opened the plug out and turned the engine on. With plug out I had no flow. once you open it if you have oil flow then there is something wrong with the spool. if no flow than at the diverter block flow is not diverted. I don't know if you have a relief device for your loader system as well.

Pic below shows the valve and spring to adjust the pressure.

I'm thinking your issue might lie in the spool control valve. test out the relif device and let us know. I thing we might be getting close.

JC,

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Toolhawk, I still think something is allowing oil to return to the reservoir before it is being routed to the 3PH whether it be a blown seal in the 3PH control valve or somewhere else. The system pressure relief valve is adjusting overall hydraulic pressure and would effect all systems. I sincerely doubt it is related to your problem.

JC-jetro

Elite Member

Jim,

In my rig without a loader, hyd pump discharge is directly routed to the Relief device. There is nothing in between pump discharge and relief device on my rig. In tool hawks case there is going to be some hyd block (diverter or whatever) that sends flow to loader and or 3 point. If he takes the plug out at the relief and no flow then for sure the problem lies on the diverter/hyd block. If he has flow there (what a mess it makes ) then the only thing from that point to the lift system is the lift spool valve. He needs to establish how far the flow goes and where it stops and why?

) then the only thing from that point to the lift system is the lift spool valve. He needs to establish how far the flow goes and where it stops and why?

JC,

In my rig without a loader, hyd pump discharge is directly routed to the Relief device. There is nothing in between pump discharge and relief device on my rig. In tool hawks case there is going to be some hyd block (diverter or whatever) that sends flow to loader and or 3 point. If he takes the plug out at the relief and no flow then for sure the problem lies on the diverter/hyd block. If he has flow there (what a mess it makes

JC,

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

He needs to establish how far the flow goes and where it stops and why?

JC,

I could not agree with you more. I'd love to have a schematic diagram of the 1900's hydraulic system to see how flow is supposed to go with a loader attached.

EDIT: Look at the diagram below. The part # 16 in this diagram is inserted between the relief valve and the 3PH control valve. That's what taps flow/pressure off for the loader, but I see no place on it to test pressure. I think that is the diverter block.

JC-jetro

Elite Member

I could not agree with you more. I'd love to have a schematic diagram of the 1900's hydraulic system to see how flow is supposed to go with a loader attached.

EDIT: Look at the diagram below. The part # 16 in this diagram is inserted between the relief valve and the 3PH control valve. That's what taps flow/pressure off for the loader, but I see no place on it to test pressure. I think that is the diverter block.

Jim,

#16 is a hyd block that is between the spool valve and the relief device. The pics below is from another 1700 that I looked at. That rig did have a loader on it. in the fashion pictured below there is one relief device that works both loader and 3 point. I was trying to locate a block like that to make a rear remote for a splitter or something. I don't know if OP's loader is configured like the pics below.

If he removes the cap on the relief device and there is flow there then for sure spool got an issue or diverter block has blockage. There is remote possibility (highly unlikely) that relief check at the head is stuck wide open. it is very easy to take the diverter block and clean it up and push some compressed air in it. The o-rings in the block can be replaced by a metric o-ring from HF.

JC,

two lines out of the hyd block going to loader valve.

two lines going to loader spool valve, two going to lift and two to curl.

close up pic of the loader spool valve.

jinman when you say you would like schematic diagram of the 1900's hydraulic system , what more are u looking for than u posted ? that is my system ?

pulled relief valve screw out , your right WHAT A MESS!!, SHOT OUT 3PLUS FEET!!

pulled relief valve screw out , your right WHAT A MESS!!, SHOT OUT 3PLUS FEET!!

JC-jetro

Elite Member

jinman when you say you would like schematic diagram of the 1900's hydraulic system , what more are u looking for than u posted ? that is my system ?

pulled relief valve screw out , your right WHAT A MESS!!, SHOT OUT 3PLUS FEET!!

Cool, we're getting closer.

Now, do you have a hyd block as I pictured on my previous post. If so, the hyd block might have a blocked port or your 3 point spool valve is blocked or diverting all flow back to diffy. If I were you and had a box of HF assorted metric 0-rings, I'd then remove the relief device, take a hyd block off, clean and blow air in it to make sure all internal ports are open. I'd think that just might do the trick. I hope you will not have do any dis assembly of lift spool valve. That would be a lot more involved and expensive.

JC,

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

jinman when you say you would like schematic diagram of the 1900's hydraulic system , what more are u looking for than u posted ? that is my system ?

Yes, that's the piping, but not the complete system showing the 3PH control valve internally. It really doesn't matter if you can't see or get to anything to test pressure. Knowing how it works doesn't do you any good if you can't test it. From that aspect, you are completely right that I don't need anymore than what we already have. As much as I'd like to know it, I can't do much with the info if I had it.

I'm going to suggest that if you remove that tap block as JC suggested, that you put the relief valve back on without the block so that the loader is eliminated from the circuit. If the 3PH does not then work, then you know you have to pull off your control valve to do seal replacement or repair.

ok i did pull spool apart, not to worry I teach machining and fabrication and repair all my own equipment,lathes , milling machines , power shears....but this is kicking my butt!!!! ok worry !! it all came apart as it should except the slotted port #21 check valve seat, it is TIGHT!!! , Will make a tool to fit slot better and get it out, everything else is clean and free ,all o rings looked good,