timb

Veteran Member

- Joined

- Jun 14, 2002

- Messages

- 1,058

- Location

- Southwest PA

- Tractor

- Deere 4710/reverser, JD 318 (still needs TLC), JD LT160

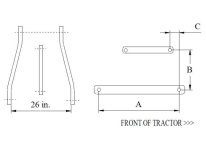

Every chart I've been able to find listing the standard dimensions for 3-point hitches seems to only list the draft arm spacing (at the rear) and the various ball/pin sizes involved. Are there actually standard dimensions for the rest of the geometry of the hitch? Referring to the attached drawing, are there standards for...

1) the horizontal length of the draft arms (pin-to-pin) - dimension "A" in the drawing...

2) the vertical height of the front pivot for the center or top link above the draft arms - dimension "B" in the drawing...

3) the horizontal 'trailing' (or leading?) dimension of the front center or top link pivot from the front pivot of the draft arms - dimension "C" in the drawing...

Anyone have any scoop on the geometry?

1) the horizontal length of the draft arms (pin-to-pin) - dimension "A" in the drawing...

2) the vertical height of the front pivot for the center or top link above the draft arms - dimension "B" in the drawing...

3) the horizontal 'trailing' (or leading?) dimension of the front center or top link pivot from the front pivot of the draft arms - dimension "C" in the drawing...

Anyone have any scoop on the geometry?