hbarski

Bronze Member

- Joined

- Apr 3, 2005

- Messages

- 68

- Location

- Tenn/Arkansas

- Tractor

- 3930 Ford/Newholland Mitsubishi MT2001D CASE 580 CK

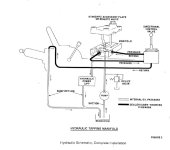

I have a 3930 with a hydraulic heat problem. The tractor has front and rear remotes that power a FEL and the till-n-trim cylinders on the 3-point. I am trying to install a grapple to the FEL and I am beginning to think I may have "bought" a hydraulic problem. Tractor is a 93 model that I bought back in June of 05.

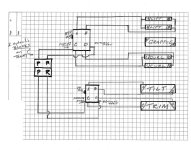

See the attachment for a schematic.

My question is, shouldn't this be a series circuit? I have two thin adapter plates installed for the hydraulic tapoff and return.

Should I reroute the hydraulics to a series circuit "before" I install the grapple control valve?

If I install another valve to control the grapple, will I be inducing more heat, if I tap into the power beyond on the FEL circuit?

I could use some expert 3930 hydraulic advice.

See the attachment for a schematic.

My question is, shouldn't this be a series circuit? I have two thin adapter plates installed for the hydraulic tapoff and return.

Should I reroute the hydraulics to a series circuit "before" I install the grapple control valve?

If I install another valve to control the grapple, will I be inducing more heat, if I tap into the power beyond on the FEL circuit?

I could use some expert 3930 hydraulic advice.