Yep, that's the pressure they engineered it for, just like the way Dodge, FMC or GM engineers design their vehicles & we all know nobody tries to get any additional power out of them right? Maybe that's why the automotive aftermarket is such a thriving industry, or perhaps the performance wheel/tire industry, I'm sure some engineers hate to see the vehicles they design modified, but it happens everyday, and yes they are still operating just fine. How about the tire & wheel combinations you see on 4 x 4 trucks.......all of that additional unsprung weight (and various backspacing distances) can't be good, but they're going up & down the road everyday.

Equipment is made a certain way because it will fit the needs of a broader user network, it doesn't mean it can't be modified to fit an individuals want's or needs and still operate trouble free for years. Sometimes a bit of modification is the difference to making equipment more useable; how many older JD tractors (larger ones, not CUT's) are running around this country that have been turned up over spec to accomodate larger plows, discs etc? Or maybe that Road tractor (tractor/trailer) that has had the fuel turned up a bit just so it will pull that heavier load over the mountain a bit faster? Need I go on? That's right now we're talking, a farmer or a truck driver has a choice to either turn his machine up to make it more useable (even if it is outside of spec) or to leave it stock & be unhappy with the performance; I know plenty of both that have opted to go through with the mods anyway.

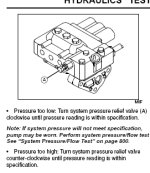

While modifications may not be for all, I for one still like to make my own choices and in some cases I will choose to modify if necessary. If the small amount of pressure increase was so critical to the engineers, why did they make it so easy to adjust? They could have just as easily made a pressure relief valve with less range or even one that was not adjustable at all.