Shield Arc

Super Member

I cut my 1 1/2-inch dies 2-inches long. I made the lower dies so they will spin, I don't know if that's necessary. The 1-inch ram is 8 1/2-inches long, I couped it to get a good fit on the upper 1 1/2-inch die.

Are you talking about using the 2x4 rectangular tubbing for the side rails? If so I would sure think it will work, the side rails are in tension. I was surprised how little effort it takes to bend these coupons. Note to date I've haven't done anything thicker than 3/8-inch.

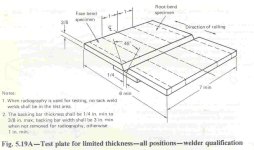

Here's a couple AWS plate tests. I've been told the side bend is the hardest to pass.

Are you talking about using the 2x4 rectangular tubbing for the side rails? If so I would sure think it will work, the side rails are in tension. I was surprised how little effort it takes to bend these coupons. Note to date I've haven't done anything thicker than 3/8-inch.

Here's a couple AWS plate tests. I've been told the side bend is the hardest to pass.