ADin

Silver Member

megotatractor,

Keep us posted on what you find and count me in on as having near identical symptoms. I also notice things seems a bit louder over time. To make things worse, I accidentally hit a stump this past spring and ended up bending a blade pretty good. This was the impetus for the start of my investigations, I ended up replacing blades and using the 2" flanges + long pipe trick to restraighten the deck as the stump hit caused a slight deck deflection. My mower performance was fixed and the noise improved, but still louder than I thought I had remembered when new. I found I could grab the blade (or sprindle from below), and under the right conditions product a very slight motion and click type noise (imagine applying slight up/down force on the blade, not rotation, which would cause a sideways deflection on the spindle shaft). Perhaps at most 1/16" deflection at the blade tips. I had about 270 hours (majority mowing) at that time and do a pretty good job keeping the spindles greased, but I thought perhaps there was spindle wear. I inspected the spindle, found nothing, but ultimately replaced the spindle bearings and shaft. Still no change and afterwards, I founds I could still produce the slight click noise so I assume it is result of natural play in the bearings, though deflection may be a touch less, but it's hard to say. I then determined that at just the right spot of blade rotation I could get one of the other spindles to also make the clicking noise.

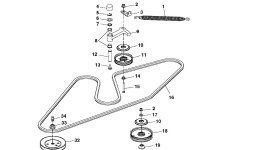

The belt had rubbed the deck on the back left side as looking down from the seat as well as the gear box bracket a bit, but I think that it only rubbed when the blade was bent. The belt seems to still be flapping more than I think it should, but I don't think it's actually rubbing anything currently. I also thought about and had suspicion of the tensioner spring, as I couldn't find anything else to point to, however, I doubt this will be the issue as even when I artificially "assist" the tensioner spring, I don't seem to see an appreciable difference in deflection of the belt. I had left this item on my to do list, but tabled it for the past couple of months. This thread has got me back on the topic as this is annoying to the engineering side of me not being able to put this to bed.

My current guess is that the belt is naturally a little flapping and with age we are getting additional vibration pulses through the pto shaft aggravating the situation. I would like to confirm by checking out a new JD2305 w/ 62c at that dealership to compare (or if someone with low hours could respond).

Keep us posted on what you find and count me in on as having near identical symptoms. I also notice things seems a bit louder over time. To make things worse, I accidentally hit a stump this past spring and ended up bending a blade pretty good. This was the impetus for the start of my investigations, I ended up replacing blades and using the 2" flanges + long pipe trick to restraighten the deck as the stump hit caused a slight deck deflection. My mower performance was fixed and the noise improved, but still louder than I thought I had remembered when new. I found I could grab the blade (or sprindle from below), and under the right conditions product a very slight motion and click type noise (imagine applying slight up/down force on the blade, not rotation, which would cause a sideways deflection on the spindle shaft). Perhaps at most 1/16" deflection at the blade tips. I had about 270 hours (majority mowing) at that time and do a pretty good job keeping the spindles greased, but I thought perhaps there was spindle wear. I inspected the spindle, found nothing, but ultimately replaced the spindle bearings and shaft. Still no change and afterwards, I founds I could still produce the slight click noise so I assume it is result of natural play in the bearings, though deflection may be a touch less, but it's hard to say. I then determined that at just the right spot of blade rotation I could get one of the other spindles to also make the clicking noise.

The belt had rubbed the deck on the back left side as looking down from the seat as well as the gear box bracket a bit, but I think that it only rubbed when the blade was bent. The belt seems to still be flapping more than I think it should, but I don't think it's actually rubbing anything currently. I also thought about and had suspicion of the tensioner spring, as I couldn't find anything else to point to, however, I doubt this will be the issue as even when I artificially "assist" the tensioner spring, I don't seem to see an appreciable difference in deflection of the belt. I had left this item on my to do list, but tabled it for the past couple of months. This thread has got me back on the topic as this is annoying to the engineering side of me not being able to put this to bed.

My current guess is that the belt is naturally a little flapping and with age we are getting additional vibration pulses through the pto shaft aggravating the situation. I would like to confirm by checking out a new JD2305 w/ 62c at that dealership to compare (or if someone with low hours could respond).