You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

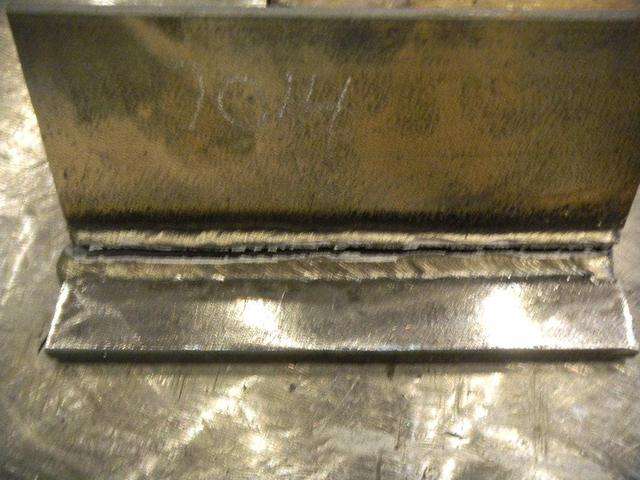

7014 Break test.

- Thread starter Shield Arc

- Start date

/ 7014 Break test.

#1

LD1

Epic Contributor

So the end results are??

6010......10 blows

6011......8 blows

7014......10 blows

7018......18 blows +

I personally still like my 7014.

I have built/repaired countless things with it and yet to have anything fail due to a poor weld.

Just to entertain us some more, how about doing that same test with a MIG weld and possibly a TIG weld just so we can see how the other forms of welding stack up:thumbsup:

And...You sure you werent taking baby swings at that 7018 to get it to last 18 hits:laughing:

6010......10 blows

6011......8 blows

7014......10 blows

7018......18 blows +

I personally still like my 7014.

I have built/repaired countless things with it and yet to have anything fail due to a poor weld.

Just to entertain us some more, how about doing that same test with a MIG weld and possibly a TIG weld just so we can see how the other forms of welding stack up:thumbsup:

And...You sure you werent taking baby swings at that 7018 to get it to last 18 hits:laughing:

wdchyd

Elite Member

So the end results are??

6010......10 blows

6011......8 blows

7014......10 blows

7018......18 blows +

:

Ahhhh.....You're forgetting about 6013 with 3 blows..??

I've said it before.....I'll stick to my 7018 thanx..!!

wdchyd

Elite Member

Is welding kinda like tying knots......"If you can't tie a knot...Just tie alot"...:laughing:

shaley

Platinum Member

Should there be any difference at all in the strength of the 70xx welds?

rankrank1

Platinum Member

- Joined

- May 23, 2007

- Messages

- 749

- Location

- SW OH - near Dayton, OH

- Tractor

- 1978 Kubota L285, 1951 Farmall h, 1946 Farmall m, 1950 John Deere A, 1953 Ford NAA Golden Jubilee, 195? Ford 850, 1948 Case DC, 1948 Case SC

Should there be any difference at all in the strength of the 70xx welds?

The 70xx only represents tensile strength, and yes all 70XX will be silmilar in tensile strength of roughly 70,000 pounds minumum. That said, tensile strength is only part of the factor in determining overall strength of a weld.

Ductility also is an important factor too. Metal or welds can be strong in tensile mode, but extemely brittle in bending modes or shock loads or vibration modes.

Example: Take a hand file that you file metal or wood with. It is strong enough to pull a locomotive if you used it longways and applied a steady non-shock type load. Yet clamp it in a vice and you could probably easily snap it half with a small hammer with a small blow to the side of it.

Mark @ Everlast

Advertiser

The 70xx only represents tensile strength, and yes all 70XX will be silmilar in tensile strength of roughly 70,000 pounds minumum. That said, tensile strength is only part of the factor in determining overall strength of a weld.

Ductility also is an important factor too. Metal or welds can be strong in tensile mode, but extemely brittle in bending modes or shock loads or vibration modes.

Example: Take a hand file that you file metal or wood with. It is strong enough to pull a locomotive if you used it longways and applied a steady non-shock type load. Yet clamp it in a vice and you could probably easily snap it half with a small hammer with a small blow to the side of it.

Any chance of stretching the welds? lol I imagine that is basically what's going on when you hammer it the other way.