A lot of variables. Location and well depth.

Well depth was 500 so that's :

- 480 feet of SCH 120 PVC drop pipe (100 feet perforated pipe) with Stainless Steel Couplers

- 480 feet of well cable wire

- pump shroud & torque arrestor

- 3 stainless check valves

- Stainless 3HP Goulds Pump & Motor

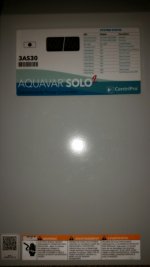

- VFD Controller

- 5-year parts and labor warranty

A standard well pump at that depth that has hard starts could break the PVC pipe. Well companies usually will not install a standard well pump at that depth using PVC. They will require galvanized (rust) or stainless steel ($$$) drop pipe. A soft-start VFD Gould's pump starts to ramp up slowly and then shuts down slowly. A standard pump just has ON/OFF and the torque created from the hard starts/hard stops puts extreme stress on PVC pipes that deep. A Goulds VFD doesn't do that and is gentle on the pipe when it starts/stops. It uses 3-phase power to control the pump.

There is not one-size-fits-all when it comes to wells. What works in Alabama might not work in Utah or Arizona. A 50' deep well vs a 500' deep well creates different challenges. Some people get 100gpm while others might only see 3gpm. My well produced around 23GPM until the well pump ran out of HP and couldn't keep up with the incoming water. So I probably have around 30gpm or more production.