You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advice for a TIG beginner?

- Thread starter California

- Start date

- Views: 20794

More options

Who Replied?

/ Advice for a TIG beginner?

#11

LD1

Epic Contributor

As shield mentioned, with proper gas, you "can" weld aluminum. Most don't because 1 bottle of 100% argon is easier. I have never used DC on aluminum, because have always had a AC capable machine, so never been curious to buy the gas and try.

For tungsten, I like ceriated tungsten. That way I don't have to keep track when going from aluminum, stainless and steel. One type does all.

For farm type repairs on on that air cooled machine I'd stick with 1/8" tungsten too unless you start welding really thin stuff.

Another thing, I didn't see anywhere on that machine to swap from dcen to dcep (sometimes the machine does it on its own when selecting stick vs Tig mode). So assuming how you hardwire the cables, make sure it's dcen for Tig. And most stick welding is dcep

For tungsten, I like ceriated tungsten. That way I don't have to keep track when going from aluminum, stainless and steel. One type does all.

For farm type repairs on on that air cooled machine I'd stick with 1/8" tungsten too unless you start welding really thin stuff.

Another thing, I didn't see anywhere on that machine to swap from dcen to dcep (sometimes the machine does it on its own when selecting stick vs Tig mode). So assuming how you hardwire the cables, make sure it's dcen for Tig. And most stick welding is dcep

vidio1

Bronze Member

If you got a great deal on it then get a bottle, watch some of this guy's videos Welding Tips and Tricks - TIG, MIG, Stick and a pantload of other info and run with it. All depends on what you might need to weld. If you're on the fence about it but still interested in Tig welding then sell it and get an AC/DC machine. The website I posted has some reviews on affordable Chinese machines.

Fallon

Super Member

Jody at Welding Tips & Tricks already linked is a great resource.

Just remember, TIG is a clean process. Your material needs to be spotless for good results. Cleaning off fingerprints with acetone kind of clean. You can do it on not perfectly clean material, but your welds will look like crap & probably be as structurally sound.

A down & dirty tractor/farm repair process it is not.

I'm not great at TIG, but for some reason it's what I learned on & do most. I'm moving over to stick because I'm mostly repairing & fabricobling on tractor imiments & semi-salvaged materially these days. SO much faster to stick than TIG, even if you don't count the cleaning & prep, which often takes more time than the actual welding.

TIG looks so much better & is so much more precise when you do it right though.

Just remember, TIG is a clean process. Your material needs to be spotless for good results. Cleaning off fingerprints with acetone kind of clean. You can do it on not perfectly clean material, but your welds will look like crap & probably be as structurally sound.

A down & dirty tractor/farm repair process it is not.

I'm not great at TIG, but for some reason it's what I learned on & do most. I'm moving over to stick because I'm mostly repairing & fabricobling on tractor imiments & semi-salvaged materially these days. SO much faster to stick than TIG, even if you don't count the cleaning & prep, which often takes more time than the actual welding.

TIG looks so much better & is so much more precise when you do it right though.

CincyFlyer

Veteran Member

As shield mentioned, with proper gas, you "can" weld aluminum. Most don't because 1 bottle of 100% argon is easier. I have never used DC on aluminum, because have always had a AC capable machine, so never been curious to buy the gas and try.

For tungsten, I like ceriated tungsten. That way I don't have to keep track when going from aluminum, stainless and steel. One type does all.

For farm type repairs on on that air cooled machine I'd stick with 1/8" tungsten too unless you start welding really thin stuff.

Another thing, I didn't see anywhere on that machine to swap from dcen to dcep (sometimes the machine does it on its own when selecting stick vs Tig mode). So assuming how you hardwire the cables, make sure it's dcen for Tig. And most stick welding is dcep

Yeah, with the proper gas (helium) and skill, you can weld aluminum with DC (you can even use flux/argon). But by using AC you get a "self-cleaning" of the oxides on the aluminum-you can see it happen-making it much easier for a novice (not that aluminum can't be tricky even with experience; welding high-silicon die castings that have spent their lives in an oil bath is a PITA. Just did one last weekend). I'd say that DC TIG helium welding aluminum just ain't for beginners. But most folks don't have a lot of aluminum work, and don't want two gas bottles, so the DC unit should be fine for most farm usage, especially with the stick option. (I bought a Square Wave about 15 years ago after my two previous machines gave up the ghost; it still works fine, but when it fries, I'll probably go with an imported inverter unit, as I don't use this for work any longer.)

woodlandfarms

Super Member

- Joined

- Jul 31, 2006

- Messages

- 6,149

- Location

- Los Angeles / SW Washington

- Tractor

- PowerTrac 1850, Kubota RTV x900

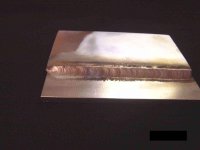

This aluminum weld was made on DC, with 100% helium. With 100% helium, it takes about 1/2 the amps to do the same thing on AC with 100% argon.

Never bought helium for welding, isn't this crazy expensive?

Shield Arc

Super Member

I bought the bottle years ago, I don't remember what I paid for it. With helium being so light, you have to run around 30-cfh.Never bought helium for welding, isn't this crazy expensive?

woodlandfarms

Super Member

- Joined

- Jul 31, 2006

- Messages

- 6,149

- Location

- Los Angeles / SW Washington

- Tractor

- PowerTrac 1850, Kubota RTV x900

You end up with a high voice when done?

California

Super Star Member

- Joined

- Jan 22, 2004

- Messages

- 16,593

- Location

- An hour north of San Francisco

- Tractor

- Yanmar YM240 Yanmar YM186D

Ok, I got the Grizzly welder out today and tried a little Stick welding.

First, it has lots of switches but there is no ac/dc switch. The amperage knob is the only control relevant for stick.

From what I'm reading here I would need both the argon bottle for TIG and then a separate helium bottle if I wanted to weld aluminum. And dc-only is not well suited to welding aluminum. And I don't have anything made of aluminum that would ever need welding. So the aluminum option is off the table. TIG - undecided. I'm looking for applications where it would be a superior choice, don't see any here at the moment.

Today's stick welding project: I started with an angle-iron bed frame, cut it down, and welded it to match dimensions of a heavy bin (holds a couple hundred lbs of big lag bolts) that I slide under a workbench. Also drilled out rivets and turned around the bedframe's caster mounts to make this new rolling frame as low as possible. Welding the caster mounts back on in their new position went ok but using 6011 on old painted - and slightly rusty - bed angle iron didn't produce the nice appearance I would show anyone. Grinding the spots clean that were to be welded didn't seem to make any prettier welds so after the first one I just burned through what was there. All four looked identical after this.

3/16 6011 seems to like 60~80 amps on the digital readout. It showed 130, the rated stick maximum, when the electrode stuck. 1/8 6011 needs around 90 amps on the readout and showed 142 amps once when the electrode stuck. Both sizes left rough uneven welds (probably my technique as well as the dirty metal) so I ground the welds and went back over them with 3/16 6013. That looked smoother. I have read somewhere that bedframe iron is some alloy or junk steel that is hard to weld - anybody know if there is any truth to this?

However - I'm not seeing that I have gained anything over the welder I started with, a 230 amp ac stick unit. Wards PowrKraft from the 1960's, same specs as a Tombstone (but a slider lever/core slug for amperage control). I can - have - done rough work like what I did today using that. And now that I replaced my Century 130 (110v mig) with the used HF Mig180 shown in the photo above, I think the big stick welder plus the HF mig might be all the welders I need.

First, it has lots of switches but there is no ac/dc switch. The amperage knob is the only control relevant for stick.

From what I'm reading here I would need both the argon bottle for TIG and then a separate helium bottle if I wanted to weld aluminum. And dc-only is not well suited to welding aluminum. And I don't have anything made of aluminum that would ever need welding. So the aluminum option is off the table. TIG - undecided. I'm looking for applications where it would be a superior choice, don't see any here at the moment.

Today's stick welding project: I started with an angle-iron bed frame, cut it down, and welded it to match dimensions of a heavy bin (holds a couple hundred lbs of big lag bolts) that I slide under a workbench. Also drilled out rivets and turned around the bedframe's caster mounts to make this new rolling frame as low as possible. Welding the caster mounts back on in their new position went ok but using 6011 on old painted - and slightly rusty - bed angle iron didn't produce the nice appearance I would show anyone. Grinding the spots clean that were to be welded didn't seem to make any prettier welds so after the first one I just burned through what was there. All four looked identical after this.

3/16 6011 seems to like 60~80 amps on the digital readout. It showed 130, the rated stick maximum, when the electrode stuck. 1/8 6011 needs around 90 amps on the readout and showed 142 amps once when the electrode stuck. Both sizes left rough uneven welds (probably my technique as well as the dirty metal) so I ground the welds and went back over them with 3/16 6013. That looked smoother. I have read somewhere that bedframe iron is some alloy or junk steel that is hard to weld - anybody know if there is any truth to this?

However - I'm not seeing that I have gained anything over the welder I started with, a 230 amp ac stick unit. Wards PowrKraft from the 1960's, same specs as a Tombstone (but a slider lever/core slug for amperage control). I can - have - done rough work like what I did today using that. And now that I replaced my Century 130 (110v mig) with the used HF Mig180 shown in the photo above, I think the big stick welder plus the HF mig might be all the welders I need.

Last edited:

LD1

Epic Contributor

You don't need Helium to tig weld, straight Argon is fine for what most people will ever do.

If you would have actually read the thread, you would have realized he has a DC ONLY welder. And lacking an AC option....NO you CANNOT weld aluminum with straight argon:confused2: