edozun

New member

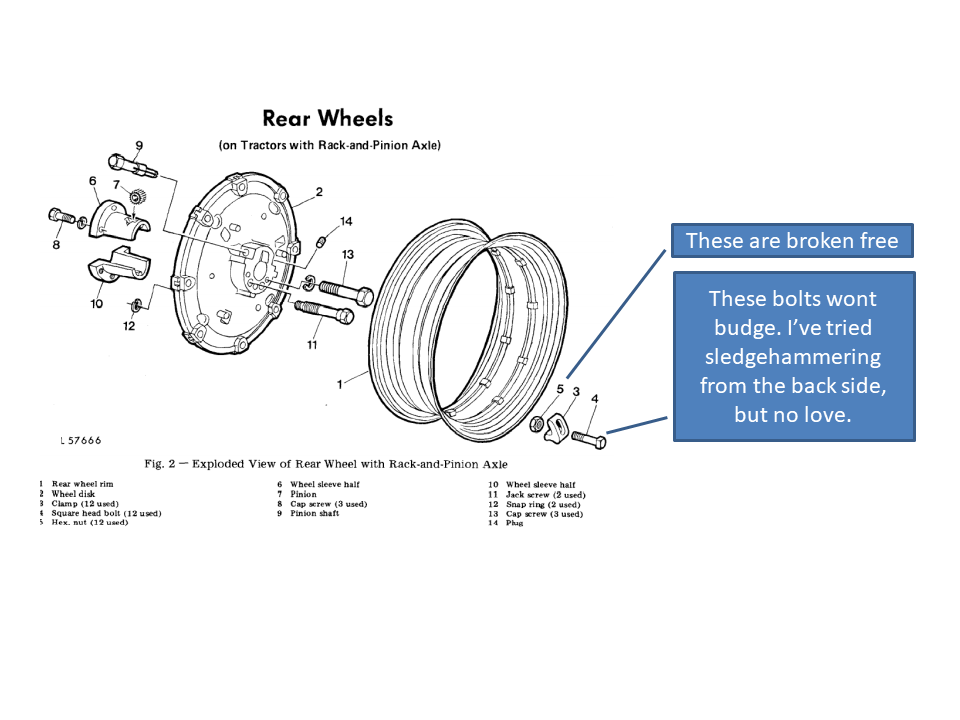

My rim rotted at the valve stem and all the fluid ran out. I've got a replacement rim. The traveling service tech said he didn't want to mess with the wheel due to the wedges being a pain. I've broken the 8 nuts loose (5) and juiced up the bolts (4), but they do NOT want to come out. Any tips on how to get those bolts (4) and clamps (3) to come free from the wheel disk (2)? Thanks in advance!