Yes, you would clean the metal by removing all the paint.

try to find the ends of the crack.

drill a small hole at each end, this is to try and prevenct the crack from growing any farther.

grind out the crack to bevel the edges on each side of the crack so you can get penetration with your weld along the crack.

grind your weld down to the surface of the tank.

a patch of metal the same thickness of the tank, with the paint removed completely where the patch will reside.

form the metal to the shape of the tank surface and then tack it in place.

finish by welding the perimeter of the patch.

it may be difficult to repair due to the fact that most of the time the bracket is located on the top cap and the surface is not flat.

forming it to the shape of the tank is more difficult there.

Once again it is better to look for a replacement tank from a shot compressor due to unseen metal fatigue/cracks.

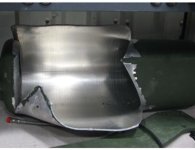

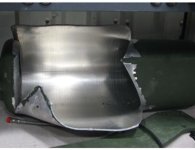

this is the outcome when one releases. it is not always a small leak.

best to look for a newer tank, and solve the vibration problem.