J_J, Don't you sleep?

I appreciate all your advice.

Once I take the QD off the hose that I ran into the bucket there is no restriction in the line. The hose has half inch fittings on it and I would guess it is a half inch hose. The remote had never been used in the 30 years we have owned the tractor until I got the dump wagon last summer. In order to use the dump wagon, I had to change the QD on the remote hose. When I took the old QD off I realized the fluid in the remote hoses had turned to gunk so I took them off and cleaned them out throughly so I know there is no restriction in them. You are right about the flow, I don't know what I was thinking. When I got 2.5 quarts I thought the flow was good not thinking that it should have been gallons instead of quarts. I am a little hesitant to run the system too much without the screen in it. We did this flow test with the old screen in the system. Once I get the new screen we will try it again before I change the pump. I think when I install the new screen I should should take the whole line off between the bottom of the transmission and the pump and change all the o-rings and such to make sure we aren't getting any suction leaks.

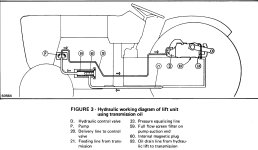

As near as I can tell there is no way to set the remote pressure relief valve. It is a cartrige type afair that just screws out. The book says when there is a problem with it that it should be changed. I didn't realize until this morning that there are separate PRVs for the 3 pt hitch and the remote. I now see them in the book. The one I took out before was the one for the remote. Next time I go to the barn, I will try and find the one for the 3 pt hitch. You are right the remote does come before the 3 pt hitch. The book says the relief on the 3pt should be between 2062 psi and 2205 psi and the remote should be between 2133 psi and 2489 psi. It tells how to test the remote on the tractor but I can't find how to test the relief on the 3 pt hitch while it is on the tractor. The way I see it, if the 3 pt. hitch will lift what I need (the PHD) without engaging the relief valve it will be OK.

Well I am going to order the screen now and then go see how fast it lifts the PHD. Thanks again.