Tscott9330

Bronze Member

I have been reading a ton on pole barn construction, and have a few books on the way in the mail, but many of you have built these before, so I would like to ask a question.

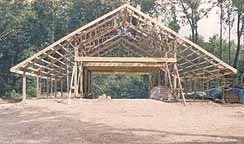

I am in the process of designing a 40' by 60' pole barn as a shop. I am investigating the possibility of using attic trusses to allow for a room over the shop. I have not seen any pole barn type buildings with attic trusses. Is there a reason for this?

Here are some PDF's of my current plan.

View attachment Shop side view 40' x 60' attic truss Model (1).pdf

View attachment Shop side view 40' x 60' attic truss Model (2).pdf

These show the front of the building (60' side) and the end of the building (40' side). As you can see on the front of the building (60' side) my posts will be spaced a max of 12' apart to allow for doors and on the rear (not shown) the posts will be set at 10' spacing. Between the tops of the posts (around the perimeter) will be 2 - 2"x12" connecting the posts. These will be notched into the top of the posts on the front and back of the posts and will be lag bolted to the posts. The trusses I will have made will rest on these 2"x12" members. Assuming the truss company specs these trusses to be 2' OC, there will be 5 or 6 trusses supported by most spans.

Will the additional weight of an attic and the future crap in it be adequately supported by these 2"x12" members?

Is this why you do not see more attic type trusses in pole barns?

Would I be better off going with a more traditionally accepted type of construction (i.e. standard 2"x4" or 2"x6" framing methods)?

What do the experts think?

Tom

I am in the process of designing a 40' by 60' pole barn as a shop. I am investigating the possibility of using attic trusses to allow for a room over the shop. I have not seen any pole barn type buildings with attic trusses. Is there a reason for this?

Here are some PDF's of my current plan.

View attachment Shop side view 40' x 60' attic truss Model (1).pdf

View attachment Shop side view 40' x 60' attic truss Model (2).pdf

These show the front of the building (60' side) and the end of the building (40' side). As you can see on the front of the building (60' side) my posts will be spaced a max of 12' apart to allow for doors and on the rear (not shown) the posts will be set at 10' spacing. Between the tops of the posts (around the perimeter) will be 2 - 2"x12" connecting the posts. These will be notched into the top of the posts on the front and back of the posts and will be lag bolted to the posts. The trusses I will have made will rest on these 2"x12" members. Assuming the truss company specs these trusses to be 2' OC, there will be 5 or 6 trusses supported by most spans.

Will the additional weight of an attic and the future crap in it be adequately supported by these 2"x12" members?

Is this why you do not see more attic type trusses in pole barns?

Would I be better off going with a more traditionally accepted type of construction (i.e. standard 2"x4" or 2"x6" framing methods)?

What do the experts think?

Tom