Travelover

Elite Member

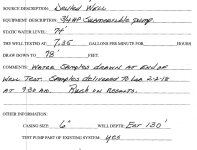

I'm starting a new thread about the same well that had suddenly provided brown water. Thankfully the water has cleared but I have a new issue.

Currently, I'm getting the sprinkling system ready and now find that the well will not maintain more than 25-ish PSI when any zone is running. For the past 5 years, the pump would hold a steady 40 to 45 PSI while any zone was operating. The well pumps up to 60 PSI fairly quickly during normal household use. It has a 40 to PSI control switch. The sprinklers have been off since October as I live in the Pacific Northwest area.

It occurs to me that I might have slime bacteria partially blocking the well pump intake, the drop pipe might be leaking or the pump itself may be weak. The 3/4 HP pump draws 7.5 amps at 240 volts, which is unchanged.

I'm fishing for ideas / tests that I can make myself before I open my wallet for the pump to be pulled. The well guy who replaced the capacitor intimated that it was probably put in with rigid PVC pipe, as his company installed it years ago and that is their practice. I have not confirmed that, but in any case I'm not up to pulling it myself.

Thanks in advance for any advice.

Currently, I'm getting the sprinkling system ready and now find that the well will not maintain more than 25-ish PSI when any zone is running. For the past 5 years, the pump would hold a steady 40 to 45 PSI while any zone was operating. The well pumps up to 60 PSI fairly quickly during normal household use. It has a 40 to PSI control switch. The sprinklers have been off since October as I live in the Pacific Northwest area.

It occurs to me that I might have slime bacteria partially blocking the well pump intake, the drop pipe might be leaking or the pump itself may be weak. The 3/4 HP pump draws 7.5 amps at 240 volts, which is unchanged.

I'm fishing for ideas / tests that I can make myself before I open my wallet for the pump to be pulled. The well guy who replaced the capacitor intimated that it was probably put in with rigid PVC pipe, as his company installed it years ago and that is their practice. I have not confirmed that, but in any case I'm not up to pulling it myself.

Thanks in advance for any advice.