DaveNay

Platinum Member

- Joined

- Aug 13, 2003

- Messages

- 835

- Location

- Waterman, DeKalb County, Illinois

- Tractor

- John Deere 855 MFWD; Oliver 1850 Gas

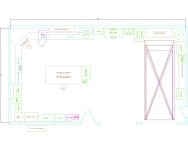

Attached is my current plan for converting my four car garage into a workshop for the farm. It will be service by a 200A electrical supply, fully insulated and drywalled. Two of the garage doors will be filled in, with the other two remaining for ocasional parking and pulling vehicles in for maintenance. THe ceilings are only 8'4", so I can't install a lift (unless someone knows of a shorty lift with limited height). I plan to do simple woodwork, metal fabrication (milling, welding, etc) as well as maintenance on all the farm equipment. Air will be hard piped throughout.

Any suggestions regarding the layout are fully appreciated. I don't currently own all of the equipment listed, but I will someday. /forums/images/graemlins/grin.gif

Thanks,

Dave

Any suggestions regarding the layout are fully appreciated. I don't currently own all of the equipment listed, but I will someday. /forums/images/graemlins/grin.gif

Thanks,

Dave