DonaldP

Gold Member

!!! UPDATE !!!

YouTube video of this post

Its amazing how things sometimes fall into place, if even for the wrong reasons.

I attached the BH92 Backhoe yesterday to do a few minor things around the yard. I hadn't used the Backhoe for about 2 weeks. About 10 minutes into cleaning out a streambed in that process I lost the dipper control down function. The control lever just flopped around in place seemingly held by a partial of the assembly.

Instantly I thought, ok what did I do?

I hadn't bumped the stick too hard to cause anything to break, I'm pretty soft on the controls overall, and the opposite stick felt just fine... it must be some kind of mechanical failure.

My first thought was to call my NEW dealership (Evans Supply) for Warranty work. That would consist of setting an appointment for a day or a week away, communication of my issue to Kubota, to the Dealership, putting the TLB onto the Trailer for transport to the dealership, and then waiting for the repair. This is what I have done in the past, is this what I should do now.

I decided to open the BH92 Control Tower to see what was going on. A 12mm wrench and in 2 minutes it was open.

There were only 4 cover bolts on the tower assembly and oddly 1 was a used orange painted bolt, while the others were bright and shiny, as they should be on a less than 20 hour $10,000 Backhoe delivered with the L3560 when it was new.

I found the issue immediately. The control valve consists of 6 identical Rod end joints which have a ball joint on one end and a threaded hole on the other.

Those rod end joints transfer the movement of the control valve sticks to the 6 individual hydraulic control valves in the valve body. The ball joints are there to provide a flexi-joint between the stick and each of the 3 valves each stick controls. (See Photos).

One of the Rod End Joints had snapped at the ball, the Rod End that controls the Dipper function of the Backhoe.

I called around for parts... nothing in stock anywhere... except for the old Dealer whom this thread is about. So off I went to grab a couple of these rod ends. Obviously it has to be a wear item to have broken at 20 hours on a 1 year old backhoe. Price - $7.58. I bought 3, not knowing if there were issues with stress fracturing on any of the remaining 5 Rod end connectors.

Two hours later I'm back and I start to remove the broken Rod End Joint. After disassembly and fitting the new Rod End Joint I found the reason why the part broke. I reassembled and began to move the control stick before final assembly with the tractor off.

Each time I moved the Dipper control up or down I could feel backpressure on the stick. It didn't feel at all like the opposite stick in that same position. So I loosened everything up a bit and poof the issue was gone. Tighten it up and the issue returned.

Something was awry here. Something was obviously bent or misaligned and I had to figure it out because I knew I had done nothing to cause any deformation of material to cause this binding. My initial though was that the stick had been bumped too hard, or something fell on the stick breaking the joint and then bending the stick base which could cause this problem.

Thank goodness for duplicitous design...

The stick on the opposite side was exactly the same as the other, and since there was no binding on that side I studied the assembly and guess what I found?

The ball portion of the Rod End Joint requires a very small washer on each side of the ball joint to allow it clearance when the shaft through the ball is pivoted. Without the washer, the rod end joint hits either the head of the bolt that holds it, or the shaft of the hydraulic plunger on the opposite side of the ball. Upon close inspection of the old broken assembly i noticed that there was a washer on only the bolt head side, the hydraulic control piston side of the ball joint had no washer, but the control on the still functional side has a washer on BOTH sides.

I looked closely at the failed part (the broken Rod End Joint I had replaced), and the tale tale signs of the story unfolded.

When the Whites Farm Supply dealer had replaced the non leaking seals on my NEW less than 2 hour usage BH92, 30 days after I had purchased the tractor new, they failed to replace the washer on one side of the bolt holding the Rod End Joint to the Hydraulic piston for the Dipper.

Each time i moved the dipper up, the Rod End Joint would contact the Hydraulic Piston to Rod End mounting, stressing the Rod End Joint and causing a stress fracture that over a relatively short period of time took out the Rod End Joint by separation of the casting material. Aluminum in general, and being a small (short) casting is shy of flexion. It was only a matter of time.

Not having THAT washer available, I cut down a larger washer and put it in the place where it should have been all along and guess what?

No binding! No back pressure, and no longer any stress at all that I could feel or see (under close examination) on the entire assembly of the Dipper. Ill need to investigate further if any of the other Rod end joints are missing a washer on either side of these assemblies on the rest of the 5 remaining Rod End Joints.

The Takeaway from this exercise/failure is that from the beginning, when the Whites Farm Supply Technician claimed to have needed to repair the 6 leaking BH92 upper seals, I was not happy that it was done without my approval or knowledge.

Furthermore, being told by folks that I shouldn't complain because I didn't have to "pay" for it isn't the point. The point is, this was a repair that ultimately caused me additional hardship and could have resulted in additional issues that I could have been subjected to at no fault of my own.

Just because "Authorized Kubota Service" might be attached to a Dealers name doesn't necessarily mean that the work they do is acceptable for the general public, or is something that's to be presumed.

Just because Kubota is paying for something under warranty does not mean that you are covered by Kubota in the event of a failure. There are lots of reasons why fixing something without involving the Dealer or Kubota, even though the unit is still under warranty, may be a better solution.

Were I to have had it repaired at Whites Farm Supply, I may never know that the result of the failure was due to improper assembly of the unit by their technician.

I appreciate the limited skills I have with respect to my early years of being a GM mechanic, along with an engineering background/education where passive and destructive testing of failure of materials (including aluminum under compressive and tensile stress) was included.

Don't let your farm and equipment dealership manage you. This is your equipment not theirs.

Photos:

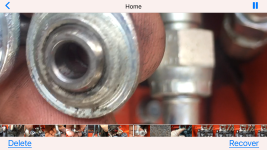

0829 shows control valve for Dipper with issue.

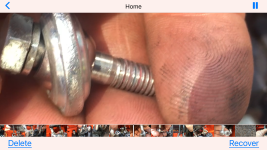

0838 shows NEW Rod End and where missing washer should go next to ball where bolt passes through.

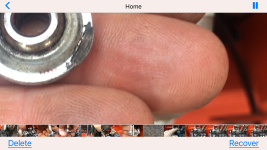

0842 shows bottom edge of old Rod End where the missing washer caused a "no Clearance" issues against the Hydraulic piston mating surface, hitting the Rod Link against the piston mount each time the dipper was moved down.(see wear pattern on bottom of old fractured Rod End where it mate3d to hydraulic dipper control piston).

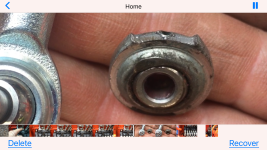

0845 shows the top edge of old Rod End where the missing washer caused a "no Clearance" issues against the Hydraulic piston mating surface, hitting the Rod Link against the piston mount each time the dipper was moved up

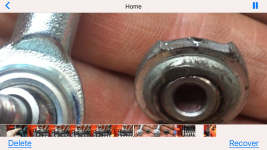

0846 shows comparison of both old and new Rod Link End

0841 shows the old fractured rod end on side where the washer was properly located, preventing contact with the Dipper piston connection point on this side - note: no wear points)

0835 shows the valve and control lever without the Rod End Link attached.

0824 shows broken assembly after BH92 cover was removed. Note washer located under head of bolt... there should have been a washer for clearance on the opposite side also, between the bolt and the control Valve bolt through mating surfaces which the dealer failed to install causing contact of the aluminum ball housing with the control valve mating surface and causing a fatigue crack and then propagation of the crack to failure..

YouTube video of this post

Its amazing how things sometimes fall into place, if even for the wrong reasons.

I attached the BH92 Backhoe yesterday to do a few minor things around the yard. I hadn't used the Backhoe for about 2 weeks. About 10 minutes into cleaning out a streambed in that process I lost the dipper control down function. The control lever just flopped around in place seemingly held by a partial of the assembly.

Instantly I thought, ok what did I do?

I hadn't bumped the stick too hard to cause anything to break, I'm pretty soft on the controls overall, and the opposite stick felt just fine... it must be some kind of mechanical failure.

My first thought was to call my NEW dealership (Evans Supply) for Warranty work. That would consist of setting an appointment for a day or a week away, communication of my issue to Kubota, to the Dealership, putting the TLB onto the Trailer for transport to the dealership, and then waiting for the repair. This is what I have done in the past, is this what I should do now.

I decided to open the BH92 Control Tower to see what was going on. A 12mm wrench and in 2 minutes it was open.

There were only 4 cover bolts on the tower assembly and oddly 1 was a used orange painted bolt, while the others were bright and shiny, as they should be on a less than 20 hour $10,000 Backhoe delivered with the L3560 when it was new.

I found the issue immediately. The control valve consists of 6 identical Rod end joints which have a ball joint on one end and a threaded hole on the other.

Those rod end joints transfer the movement of the control valve sticks to the 6 individual hydraulic control valves in the valve body. The ball joints are there to provide a flexi-joint between the stick and each of the 3 valves each stick controls. (See Photos).

One of the Rod End Joints had snapped at the ball, the Rod End that controls the Dipper function of the Backhoe.

I called around for parts... nothing in stock anywhere... except for the old Dealer whom this thread is about. So off I went to grab a couple of these rod ends. Obviously it has to be a wear item to have broken at 20 hours on a 1 year old backhoe. Price - $7.58. I bought 3, not knowing if there were issues with stress fracturing on any of the remaining 5 Rod end connectors.

Two hours later I'm back and I start to remove the broken Rod End Joint. After disassembly and fitting the new Rod End Joint I found the reason why the part broke. I reassembled and began to move the control stick before final assembly with the tractor off.

Each time I moved the Dipper control up or down I could feel backpressure on the stick. It didn't feel at all like the opposite stick in that same position. So I loosened everything up a bit and poof the issue was gone. Tighten it up and the issue returned.

Something was awry here. Something was obviously bent or misaligned and I had to figure it out because I knew I had done nothing to cause any deformation of material to cause this binding. My initial though was that the stick had been bumped too hard, or something fell on the stick breaking the joint and then bending the stick base which could cause this problem.

Thank goodness for duplicitous design...

The stick on the opposite side was exactly the same as the other, and since there was no binding on that side I studied the assembly and guess what I found?

The ball portion of the Rod End Joint requires a very small washer on each side of the ball joint to allow it clearance when the shaft through the ball is pivoted. Without the washer, the rod end joint hits either the head of the bolt that holds it, or the shaft of the hydraulic plunger on the opposite side of the ball. Upon close inspection of the old broken assembly i noticed that there was a washer on only the bolt head side, the hydraulic control piston side of the ball joint had no washer, but the control on the still functional side has a washer on BOTH sides.

I looked closely at the failed part (the broken Rod End Joint I had replaced), and the tale tale signs of the story unfolded.

When the Whites Farm Supply dealer had replaced the non leaking seals on my NEW less than 2 hour usage BH92, 30 days after I had purchased the tractor new, they failed to replace the washer on one side of the bolt holding the Rod End Joint to the Hydraulic piston for the Dipper.

Each time i moved the dipper up, the Rod End Joint would contact the Hydraulic Piston to Rod End mounting, stressing the Rod End Joint and causing a stress fracture that over a relatively short period of time took out the Rod End Joint by separation of the casting material. Aluminum in general, and being a small (short) casting is shy of flexion. It was only a matter of time.

Not having THAT washer available, I cut down a larger washer and put it in the place where it should have been all along and guess what?

No binding! No back pressure, and no longer any stress at all that I could feel or see (under close examination) on the entire assembly of the Dipper. Ill need to investigate further if any of the other Rod end joints are missing a washer on either side of these assemblies on the rest of the 5 remaining Rod End Joints.

The Takeaway from this exercise/failure is that from the beginning, when the Whites Farm Supply Technician claimed to have needed to repair the 6 leaking BH92 upper seals, I was not happy that it was done without my approval or knowledge.

Furthermore, being told by folks that I shouldn't complain because I didn't have to "pay" for it isn't the point. The point is, this was a repair that ultimately caused me additional hardship and could have resulted in additional issues that I could have been subjected to at no fault of my own.

Just because "Authorized Kubota Service" might be attached to a Dealers name doesn't necessarily mean that the work they do is acceptable for the general public, or is something that's to be presumed.

Just because Kubota is paying for something under warranty does not mean that you are covered by Kubota in the event of a failure. There are lots of reasons why fixing something without involving the Dealer or Kubota, even though the unit is still under warranty, may be a better solution.

Were I to have had it repaired at Whites Farm Supply, I may never know that the result of the failure was due to improper assembly of the unit by their technician.

I appreciate the limited skills I have with respect to my early years of being a GM mechanic, along with an engineering background/education where passive and destructive testing of failure of materials (including aluminum under compressive and tensile stress) was included.

Don't let your farm and equipment dealership manage you. This is your equipment not theirs.

Photos:

0829 shows control valve for Dipper with issue.

0838 shows NEW Rod End and where missing washer should go next to ball where bolt passes through.

0842 shows bottom edge of old Rod End where the missing washer caused a "no Clearance" issues against the Hydraulic piston mating surface, hitting the Rod Link against the piston mount each time the dipper was moved down.(see wear pattern on bottom of old fractured Rod End where it mate3d to hydraulic dipper control piston).

0845 shows the top edge of old Rod End where the missing washer caused a "no Clearance" issues against the Hydraulic piston mating surface, hitting the Rod Link against the piston mount each time the dipper was moved up

0846 shows comparison of both old and new Rod Link End

0841 shows the old fractured rod end on side where the washer was properly located, preventing contact with the Dipper piston connection point on this side - note: no wear points)

0835 shows the valve and control lever without the Rod End Link attached.

0824 shows broken assembly after BH92 cover was removed. Note washer located under head of bolt... there should have been a washer for clearance on the opposite side also, between the bolt and the control Valve bolt through mating surfaces which the dealer failed to install causing contact of the aluminum ball housing with the control valve mating surface and causing a fatigue crack and then propagation of the crack to failure..

Attachments

-

IMG_0829.JPG2 MB · Views: 156

IMG_0829.JPG2 MB · Views: 156 -

IMG_0838.PNG3.1 MB · Views: 138

IMG_0838.PNG3.1 MB · Views: 138 -

IMG_0842.PNG2.7 MB · Views: 117

IMG_0842.PNG2.7 MB · Views: 117 -

IMG_0845.PNG3.4 MB · Views: 114

IMG_0845.PNG3.4 MB · Views: 114 -

IMG_0846.PNG3.3 MB · Views: 116

IMG_0846.PNG3.3 MB · Views: 116 -

IMG_0841.PNG3.2 MB · Views: 128

IMG_0841.PNG3.2 MB · Views: 128 -

IMG_0835.PNG4 MB · Views: 114

IMG_0835.PNG4 MB · Views: 114 -

IMG_0824.JPG2.1 MB · Views: 119

IMG_0824.JPG2.1 MB · Views: 119 -

IMG_0823.JPG2.2 MB · Views: 157

IMG_0823.JPG2.2 MB · Views: 157 -

IMG_0820.JPG2.1 MB · Views: 131

IMG_0820.JPG2.1 MB · Views: 131

Last edited: