ericm979

Super Member

I used the video below, and the PTO shaft manual when shortening the shaft for the winch I got recently.

tractortoolsdirect.com

tractortoolsdirect.com

Since the shaft is short I did not leave the usual 40mm/2in of free space as that would make the length of the mating part kinda short. It's more like 20mm.

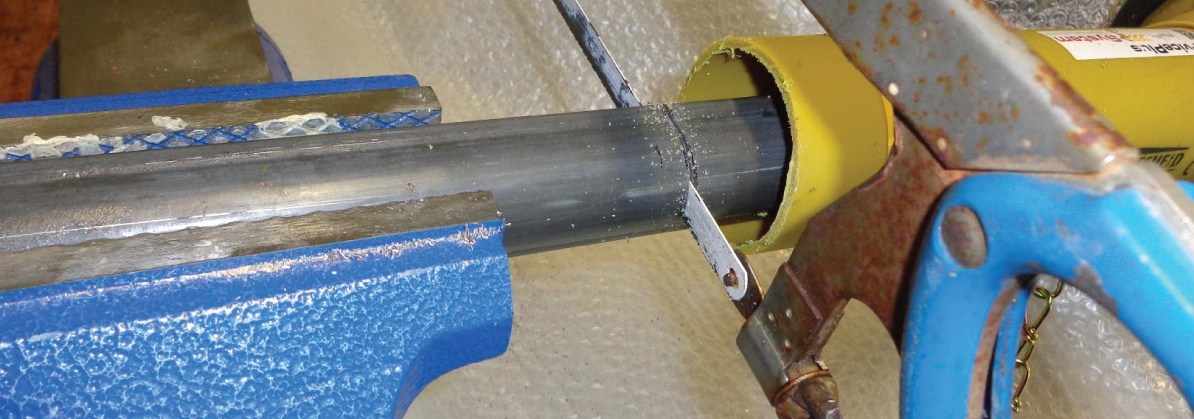

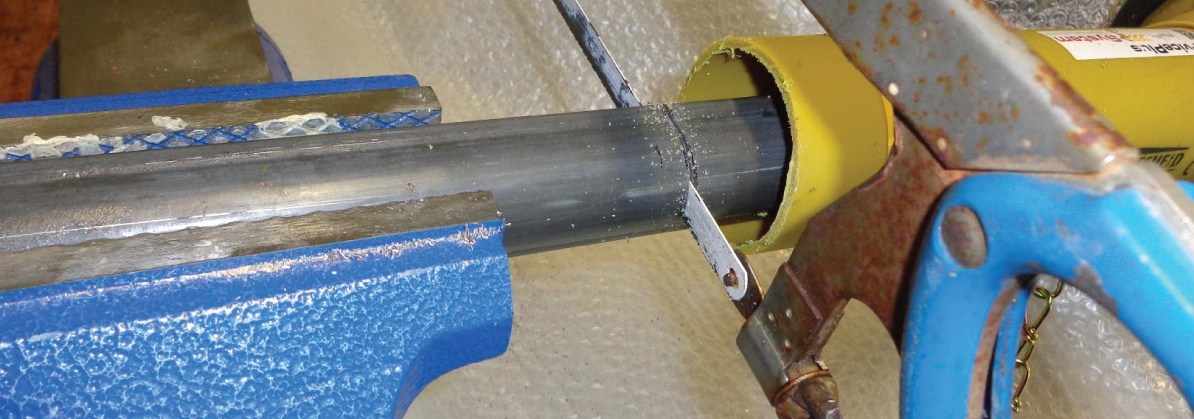

I removed the outer plastic shields so I could get clean cuts and clean up the swarf. Each manufacturer does the shields differently but the manual for my shaft showed how to remove them. It was not too difficult. A good hacksaw works fine, it's mild steel.

Don't put too much grease between the shaft halves and use a light grease. Lots of heavy grease can make it difficult to extend the shaft by hand when attaching the implement, especially when its cold. I don't leave the shafts out in the rain so mine don't need as much grease between the halves. The u-joint bearings do need grease but I try to wipe up the grease that flows out before I use the shaft so it does not make as much of a mess inside the shield.

PTO Shaft Cutting Secrets Revealed!

Learn how to properly cut a PTO shaft with this video from Tractor Tools Direct. TTD ships compact hay baling equipment directly to your door.

Since the shaft is short I did not leave the usual 40mm/2in of free space as that would make the length of the mating part kinda short. It's more like 20mm.

I removed the outer plastic shields so I could get clean cuts and clean up the swarf. Each manufacturer does the shields differently but the manual for my shaft showed how to remove them. It was not too difficult. A good hacksaw works fine, it's mild steel.

Don't put too much grease between the shaft halves and use a light grease. Lots of heavy grease can make it difficult to extend the shaft by hand when attaching the implement, especially when its cold. I don't leave the shafts out in the rain so mine don't need as much grease between the halves. The u-joint bearings do need grease but I try to wipe up the grease that flows out before I use the shaft so it does not make as much of a mess inside the shield.