downsizingnow48

Elite Member

I made this table to get more use out of my handheld bandsaw. It is very accurate.

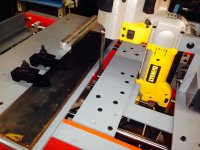

Photo 1: The frame is made of scrap aluminum plate using 1/2" bolts.

Photo 2: The work is held in place on a fixed table, and the saw moves through the work on a carriage. The carriage slides on 20mm linear bearings. There is a front plate that attaches to the foot of the bandsaw, and a rear plate that attaches to the handle. An acme thread hand wheel arrangement moves the carriage slowly and precisely. At the hand wheel end, the screw is carried in an aluminum block with a bronze bushing and two oilite thrust washers. At the carriage end, the screw turns in a standard acme nut that is attached with 4-40 cap screws.

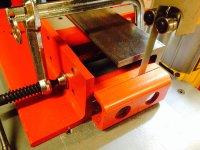

Photo 3: Each of the four mounting lugs for the carriage shafts can be adjusted for elevation. The bandsaw foot can be adjusted to get the blade parallel with the line of travel. The rear mount can be adjusted to get the blade square to the table.

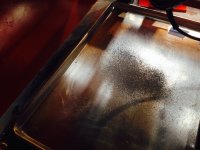

Photo 4: The table has a grid of 5/16" threaded holes for clamping large or odd sized work. There is a milled slot that takes a key as well. This is at exactly 90 degrees to the line of travel and will be used to orient fences and clamps.

Photo 5: Showing the first saw cut into the table. The saw carriage moves under the fixed table with 1/16" of clearance. Countersunk cap screws are used on the carriage and the table.

I haven't yet decided what kind of vise/fence will be most useful. Will work on that this weekend. Also will weld up a cart on casters. The footprint is 19x34. The saw will cut most of what I need using just the table. Long heavy material can be supported by roller stands on both sides and then the saw on casters can be squared to the work.

I got this idea looking at the large vertical Marvel bandsaws at the local steel supplier. At some point I might buy a horizontal band saw but this will take care of lots of work in the meantime. Also it make cuts a horizontal band saw cannot, for instance, a saw tooth edge for a backhoe thumb. That is actually why I made the table, so I can get going on the next tractor project.

Photo 1: The frame is made of scrap aluminum plate using 1/2" bolts.

Photo 2: The work is held in place on a fixed table, and the saw moves through the work on a carriage. The carriage slides on 20mm linear bearings. There is a front plate that attaches to the foot of the bandsaw, and a rear plate that attaches to the handle. An acme thread hand wheel arrangement moves the carriage slowly and precisely. At the hand wheel end, the screw is carried in an aluminum block with a bronze bushing and two oilite thrust washers. At the carriage end, the screw turns in a standard acme nut that is attached with 4-40 cap screws.

Photo 3: Each of the four mounting lugs for the carriage shafts can be adjusted for elevation. The bandsaw foot can be adjusted to get the blade parallel with the line of travel. The rear mount can be adjusted to get the blade square to the table.

Photo 4: The table has a grid of 5/16" threaded holes for clamping large or odd sized work. There is a milled slot that takes a key as well. This is at exactly 90 degrees to the line of travel and will be used to orient fences and clamps.

Photo 5: Showing the first saw cut into the table. The saw carriage moves under the fixed table with 1/16" of clearance. Countersunk cap screws are used on the carriage and the table.

I haven't yet decided what kind of vise/fence will be most useful. Will work on that this weekend. Also will weld up a cart on casters. The footprint is 19x34. The saw will cut most of what I need using just the table. Long heavy material can be supported by roller stands on both sides and then the saw on casters can be squared to the work.

I got this idea looking at the large vertical Marvel bandsaws at the local steel supplier. At some point I might buy a horizontal band saw but this will take care of lots of work in the meantime. Also it make cuts a horizontal band saw cannot, for instance, a saw tooth edge for a backhoe thumb. That is actually why I made the table, so I can get going on the next tractor project.