RichT

Silver Member

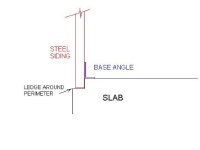

Building a steel barn for my tractor (and a few other things). Foundation is a concrete pier/slab design, ten 24" diam x 42" deep piers for the barn columns topped with a 25'x37' 3.5" slab. I'm doing all the excavation and form work myself. I'll hire some pros for the pour/finish, approx 15yds. Welcome opinions on plans as follows:

The barn plans do not specify any steel in the piers/slab. I plan to run a 5/8" rebar perimeter on the slab, connecting to 2 or 3 vertical rebars in each of the piers, with 6x6 steel mesh throughout the slab. Since I'm using a backhoe, I'm using sonotubes for the concrete piers.

I'm in SOCAL with hard clay soil. For the slab underlayment, I plan to lay down a moisture barrier, then about 2" of tamped 3/4- gravel.

The barn plans specify using hilti bolts for the anchors. I asked the plan engineering firm why hiltis instead of wet embedded anchors. They said mostly because of the precision needed for placement. There are a total of 26 anchors. I plan to set the 10 main anchors (for the steel connector columns) using 5/8" J bolts embedded 6" ahead of the pour using anchor guides attached to the forms. The remaining 16 anchors will be hiltis.

Given the size of the slab, should I set up screed pipes to help the finishers?

The barn plans do not specify any steel in the piers/slab. I plan to run a 5/8" rebar perimeter on the slab, connecting to 2 or 3 vertical rebars in each of the piers, with 6x6 steel mesh throughout the slab. Since I'm using a backhoe, I'm using sonotubes for the concrete piers.

I'm in SOCAL with hard clay soil. For the slab underlayment, I plan to lay down a moisture barrier, then about 2" of tamped 3/4- gravel.

The barn plans specify using hilti bolts for the anchors. I asked the plan engineering firm why hiltis instead of wet embedded anchors. They said mostly because of the precision needed for placement. There are a total of 26 anchors. I plan to set the 10 main anchors (for the steel connector columns) using 5/8" J bolts embedded 6" ahead of the pour using anchor guides attached to the forms. The remaining 16 anchors will be hiltis.

Given the size of the slab, should I set up screed pipes to help the finishers?