aovsurbanfarm

New member

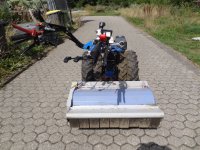

hi all, we're borrowing a sister farm's bcs at the moment that recently came back from being serviced. we're needing to do some flail mowing but there's some issue causing the bcs to move too slowly or not at all when the implement is engaged.

starts fine, shifts gears fine, has clean oil, full gas, and a new air filter. without pto engaged, all 3 speeds running correctly in forward and reverse. at first, with the flail mower on, it shifted into pto just fine but then when you released the clutch, it wouldn't go anywhere. there doesn't appear to be any issue with the pto lockout, it's in the correct position (facing away from the tractor for a front-facing implement, lever in reverse for forward motion) and is swiveling fine, but sprayed some penetrating oil just to be extra sure.

took the flail mower off to see if it would have the same problem with no attachment on it - it didn't, we let it run for a minute and could engage the pto and it would move forward at correct speed.

put the mower back on: it's not completely standstill once you engage the pto anymore, it'll move a little, but not smoothly or at the correct speed - one was kind of jumpy and slower than normal one, two was about the speed of normal one. the mower blades are spinning but not at full capacity, it cut a little grass but isn't gonna go through tall stuff like it's supposed to. you can hear it do sort of a rising and falling whine sound like a scooby-doo ghost (i wish there was car talk for tractors, sorry i can't do the noise). mower blades are clean and clear and we've never had a similar issue with the mower before.

apart from switching out the mower for a rear-facing implement and seeing if it has similar issues or if it's only for front-facing implements, we're not sure what to try next. any troubleshooting would be much appreciated, thanks yall.

starts fine, shifts gears fine, has clean oil, full gas, and a new air filter. without pto engaged, all 3 speeds running correctly in forward and reverse. at first, with the flail mower on, it shifted into pto just fine but then when you released the clutch, it wouldn't go anywhere. there doesn't appear to be any issue with the pto lockout, it's in the correct position (facing away from the tractor for a front-facing implement, lever in reverse for forward motion) and is swiveling fine, but sprayed some penetrating oil just to be extra sure.

took the flail mower off to see if it would have the same problem with no attachment on it - it didn't, we let it run for a minute and could engage the pto and it would move forward at correct speed.

put the mower back on: it's not completely standstill once you engage the pto anymore, it'll move a little, but not smoothly or at the correct speed - one was kind of jumpy and slower than normal one, two was about the speed of normal one. the mower blades are spinning but not at full capacity, it cut a little grass but isn't gonna go through tall stuff like it's supposed to. you can hear it do sort of a rising and falling whine sound like a scooby-doo ghost (i wish there was car talk for tractors, sorry i can't do the noise). mower blades are clean and clear and we've never had a similar issue with the mower before.

apart from switching out the mower for a rear-facing implement and seeing if it has similar issues or if it's only for front-facing implements, we're not sure what to try next. any troubleshooting would be much appreciated, thanks yall.