You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

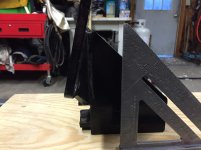

Bending 3/8" Steel Hitch

- Thread starter Underdog57

- Start date

/ Bending 3/8" Steel Hitch

#1

jix

Platinum Member

- Joined

- Sep 16, 2014

- Messages

- 611

- Location

- Fredericton, New Brunswick. CANADA

- Tractor

- 2015 Kioti CK2510HST/CAB?loader/bush hog,front blower

Take it to a pro. That metal probably has been stressed to the point of being cracked. If so, it is probably beyond a simple repair. It may need to be welded and then heat treated May be cheaper to replace it if it is to used for such high loads another time.

oldtimer 66

Gold Member

You would need some type of rose bud to get enough heat into the part to straighten it. You would need to re-mount it to the tractor but insulate it to the mounting AKA add some washers in between the mounting surface/ 3 or 4 for an air gap aka maybe some longer bolts to. You need to do this if you do not have any other method to support the part while heating and straightening. If it is a 2" receiver type you would need a long pc of tubing as a lever/ moment arm maybe be 3/4/5 feet long, or what ever you can get to use as a lever arm. The part is not heat treated as new/ maybe annealed at the most but not likely. It is just some structural steel AKA like A36. This would be a 2 person job. You running the torch and your buddy standing on the tubing lever arm. It could be a good social time with a couple of beers. After you straighten it you will need to visually check the welds for cracks and re-weld as necessary. It probably will not look as new but it should be usable again. The idea is to get the receiver parallel to the ground again. Throw some paint on it after the repair. Next would be to make your own but a little more robust of a design. I forgot one thing. Grind the HD stamping off the back side because this thing is evidently not heavy duty. LOL Later

pmsmechanic

Elite Member

- Joined

- Dec 6, 2013

- Messages

- 4,045

- Location

- Southern Alberta, Canada

- Tractor

- 4410 and F-935 John Deere, MF 245

I would price out a new piece before spending a whole lot of time on this one. If it was me you asked to straighten the piece I wouldn't bother. I have the equipment to nicely cut off the bent piece. I would then cut a new piece out of heavier steel and weld everything back together. It would be faster than trying to make a nice job of straightening the bent part.

Shield Arc

Super Member

If it were me. I'd heat it red hot with my oxygen & acetylene rose bud. Clamp it to my 3/4-inch thick welding table with bridge clamps, and work it over with a sledge hammer.

Baby Grand

Elite Member

- Joined

- Nov 12, 2007

- Messages

- 4,659

- Location

- Windsor, CT.

- Tractor

- Kubotas: L3240GST B2320HST B5100D & G5200H

^+1

Looks to me like a job for a smithy, or someone who thinks like one.

Trying to get the two deformed ears to both wind up flat and at right angles to the hitch receiver will require some finesse of heat & forces.

The steel may have work hardened, due to cold working when it deformed.

So it's going to require heating to move it without cracking and to get flat surfaces instead of ripples when you're finished.

Could be fun forge & hammer work & would make for a good journeyman smith's examination problem.

I also like oldtimer's suggestion to use a long lever to slowly move the sections where you want them to go - allows great control.

Both oldtimer & shield arc suggest that you constrain the parts that bolt to the tractor & move the receiver.

This approach guarantees that the bolt holes in the hitch will wind up in alignment with the bolt holes on the tractor.

Looks to me like a job for a smithy, or someone who thinks like one.

Trying to get the two deformed ears to both wind up flat and at right angles to the hitch receiver will require some finesse of heat & forces.

The steel may have work hardened, due to cold working when it deformed.

So it's going to require heating to move it without cracking and to get flat surfaces instead of ripples when you're finished.

Could be fun forge & hammer work & would make for a good journeyman smith's examination problem.

I also like oldtimer's suggestion to use a long lever to slowly move the sections where you want them to go - allows great control.

Both oldtimer & shield arc suggest that you constrain the parts that bolt to the tractor & move the receiver.

This approach guarantees that the bolt holes in the hitch will wind up in alignment with the bolt holes on the tractor.

Last edited:

LD1

Epic Contributor

I'd just make a new one out of heavier metal. IF you bent it once, it will happen again

rmully

Gold Member

I'd just make a new one out of heavier metal. IF you bent it once, it will happen again

I agree and fixing it by someone else may cost as much as a new one ...... you could try it yourself and see if it works out.

bigdeano

Platinum Member

Post #3 looks good to me. Looks like an easy job if you have enough heat available.

Sodo

Elite Member

- Joined

- Apr 21, 2012

- Messages

- 3,197

- Location

- Cascade Mtns of WA state

- Tractor

- Kubota B-series & Mini Excavator

It's gonna be difficult to hold that thing down to bend it back. Preheat it in a roaring campfire then fish it out and beat on it, maybe re-heating with a propane roofing torch or weedburner. Maybe you can get it in the vise & continue heating with a propane weedburner.

3/8 steel isn't hard to bend when red hot but you have a compound curve there. When its back straight, you could add bracing. But it might be designed as a soft point, to save your tractor mounts. That flat plate sure wasn't intended to take the load it got. Go easy next time.

Replacing the flat plate as said above is a reasonable suggestion too if you have the eqpt to cut a new one. It's mild steel, it wasn't and can't be heat treated.

3/8 steel isn't hard to bend when red hot but you have a compound curve there. When its back straight, you could add bracing. But it might be designed as a soft point, to save your tractor mounts. That flat plate sure wasn't intended to take the load it got. Go easy next time.

Replacing the flat plate as said above is a reasonable suggestion too if you have the eqpt to cut a new one. It's mild steel, it wasn't and can't be heat treated.