*rubs chin* i wonder if you are "binding" them sway bars. by simply raising and lowering the 3pt hitch.

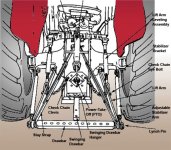

below image is from

Double HH Quality Products - Don't Compromise... Demand Double HH

i have seen it many times, the stabilizers are not on the exact same center line (the connection point on tractor itself) is lower than the connection point of the lower lift arms. the result... is if you raise the 3pt hitch lower arms you basically just bend the living daylights out of the stabilizers and/or the lift arms. which ever is weaker built will bend in the up and down fashion as your image shows NRR

if you look at your stabilizers, you have a generic round bolt or pin holes, and then you have long oval shaped holes in the stabilizers. try putting a "pin" with some washers on both sides. through those long oval holes. so when you do raise the 3pt hitch with stabilizers on. the pin will allow the stabilizers to slide. and extend or contract as needed within those long oval shape holes...

as soon as you place a bolt into the "small" generic round holes and physical lock the stabilizers from adjusting you turn the stabilizers into "stay straps" that greatly reduce how far you can lower or raise the 3pt hitch would bending the stabilizers and/or the lower lift arms.

i have seen a few stabilizer bars that are a round rod, with a spring setup. to allow some movement to extend / contract something like a hyd cylinder but limited movement of how far it can extend / contract.

======================

you might also try unhooking the bush hog from tractor. and then get someone in the seat of the tractor to raise and lower the 3pt hitch. while you, kinda hold the stabilizer bar right were it would attach you might find you might be able to adjust the "turn buckles" aka (lift arm leveling assembly) in above attach picture so that the stabilizer bar and lower lift arms were they would attach come in a better "arc" to each other as the swing up and down together.

other words, all you are worried with is keeping the hole in the lift arm and hole in end of stabilizer bar lined up as the raise and lower. you will find a "sweet spot" pending on if you shorten or length the "turn buckles" for the lower lift arms. of were the 2 holes line up. along with adjust the length of the stabilizer bar.