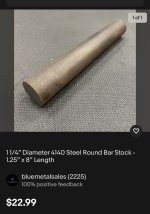

Wow, that’s pretty amazing how you got the same exact bend! Definitely a weakness in the machine here, which supports going with the larger diameter rod.

I don’t have an exact measurement on how much I had to shorten the rod on the new cylinder. I think I would have taken measurements off the machine. Why not cut off both ends and use the original pins? I wanted to make it easier in the future to change out the cylinder if I ever have to change it again, for whatever reason.

BTW: I have probably put 20-30 hours on the machine since my repair. All is well and I can’t tell that it ever happened.

I don’t have an exact measurement on how much I had to shorten the rod on the new cylinder. I think I would have taken measurements off the machine. Why not cut off both ends and use the original pins? I wanted to make it easier in the future to change out the cylinder if I ever have to change it again, for whatever reason.

BTW: I have probably put 20-30 hours on the machine since my repair. All is well and I can’t tell that it ever happened.