KentT

Elite Member

- Joined

- Mar 31, 2005

- Messages

- 2,928

- Location

- Sevierville, TN

- Tractor

- 1993 Power Trac 1430 w/Kubota diesel engine

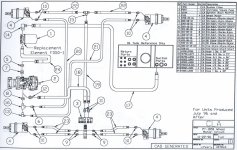

I'm thinking about my upcoming wheel motor upgrade and have a couple of questions...

1. To bleed the drive system after it has been opened up at each wheel, do I just bleed it at the charge pump the same way I would when changing the filter?

2. Should I also push the treadle in, while cranking with the spark-plug wires removed, to allow the tram pump to push the air out of the lines? If so, how would I know how long to crank it? When bleeding after changing the filter, you crank long enough to make sure the charge pump is fully primed and pumping a steady flow. Since the air introduced into the system would be on the other, output side of the tram pump, would this still be a good indicator?

3. Given the fact that it is a closed-loop system where the oil stays in there all the time (not going back to the reservoir) and only replenished by the charge pump as needed to overcome "leakage" -- do you think it would be beneficial to try draining ALL the oil out of the lines that run to the wheel motors, just to get rid of any possible contaminents in those lines?

Thanks -- I look forward to the insight...

1. To bleed the drive system after it has been opened up at each wheel, do I just bleed it at the charge pump the same way I would when changing the filter?

2. Should I also push the treadle in, while cranking with the spark-plug wires removed, to allow the tram pump to push the air out of the lines? If so, how would I know how long to crank it? When bleeding after changing the filter, you crank long enough to make sure the charge pump is fully primed and pumping a steady flow. Since the air introduced into the system would be on the other, output side of the tram pump, would this still be a good indicator?

3. Given the fact that it is a closed-loop system where the oil stays in there all the time (not going back to the reservoir) and only replenished by the charge pump as needed to overcome "leakage" -- do you think it would be beneficial to try draining ALL the oil out of the lines that run to the wheel motors, just to get rid of any possible contaminents in those lines?

Thanks -- I look forward to the insight...